Meat

The red meat industry in New Zealand, mainly comprising of sheep and beef products and co-products through processing, is a foundational pillar to this country’s success. As a global leader in the meat processing industry, it is essential that facilities consider sustainable practices with the goal of minimising environmental impact.

Whether your meat processing plant is in an urban or rural area, and you discharge wastewater to trade waste or the environment, irrigate or intend to reuse the treated wastewater, Hydroflux will always design and construct a wastewater treatment plant to suit your specific needs.

Hydroflux has experience and a range of products and designs suited for wastewater treatment from meat processing facilities including; DAF systems, anaerobic and aerobic plants, and associated sludge handling equipment. We also provide process water and advanced water treatment solutions and undertake complete design and construct contracts.

Find out more

Wastewater Treatment Process

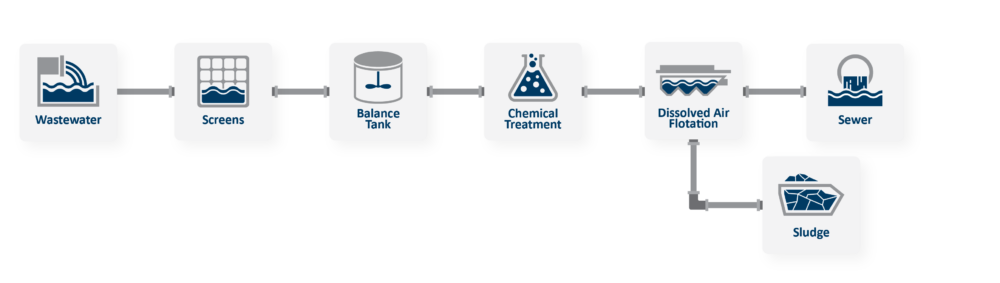

For urban facilities where wastewater is discharged to sewer as trade waste, Hydroflux would typically supply one of number of types of automated rotary screens followed by a HyDAF system which will generally enable compliance with trade waste discharge requirements.

Hydroflux will always design the system with an appropriate chemical program to suit the desired degree of treatment. Chemical programs can involve one or a combination of pH control, coagulation and flocculation.

The following diagram shows a typical wastewater treatment process for urban sites that Hydroflux would implement when wastewater is being discharged to the local sewage treatment plant.

Hydroflux will always consider each project on its own merits taking into account performance requirements, CAPEX and OPEX. We use process equipment and designs mostly sourced from our own proprietary range and will undertake turnkey design and construct contracts.

Dissolved air flotation

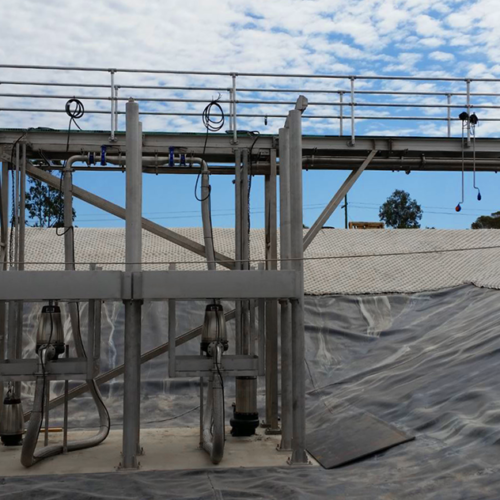

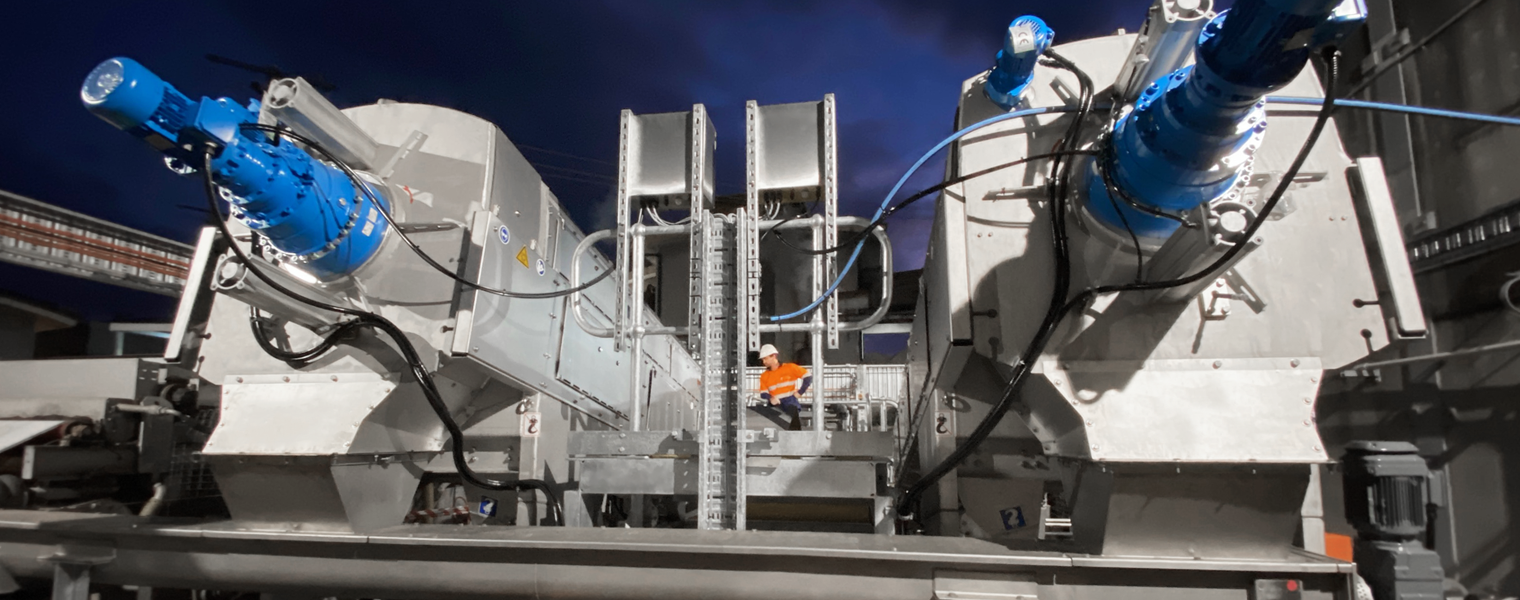

A HyDAF HD-100 V installed at a meat processing plant in WA treating combined red and green streams

The capacity of the balancing facilities, the size and configuration of the DAF, and the chemical program applied to the wastewater will always depend on type of processing facility and the discharge water quality required, which varies considerably around the regions.

Hydroflux has a comprehensive range of dissolved air flotation models ranging in capacity from 10 kL/hr to 1000 kL/hr to suit any meat processing application. The HyDAF dissolved air flotation units are configured with several options to accommodate automated removal of settled sludge and cleaning.

Sludge

Hydroflux will calculate the volume of sludge that is generated based on wastewater flow, solids load, and chemical program employed, and will evaluate sludge handling as a separate project on its own merit. In cases where sludge dewatering is viable, Hydroflux will select the most appropriate dewatering system from its extensive range of dewatering products.

A screw press was selected for dewatering DAF sludge from a meat facility which reduced the volume of sludge by more than 10-fold.

There are many factors that are used to determine the viability of onsite sludge dewatering including:

- Dewatering equipment used

- Achievable dry solids concentration and volumes

- Costs and disposal routes of slurries and dewatered cake

- Liquid and solids handling methods

- Wastewater flow

- Incoming solids load

- Level of treatment applied

- Chemical programs used

Further treatment

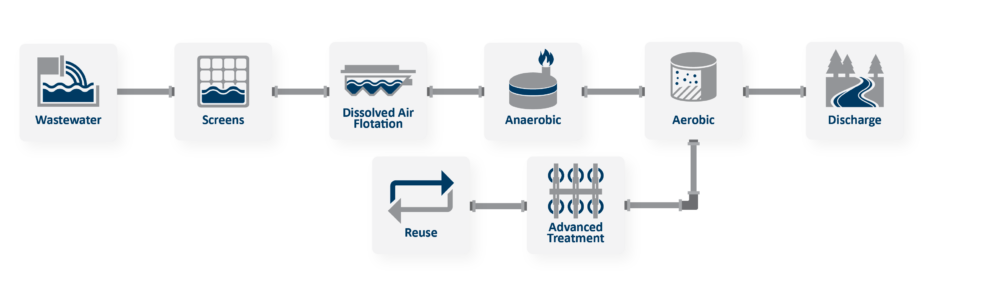

In some instances where sewer discharge requirements are outside the limitations of flotation technology, Hydroflux will design and construct a biological polishing stage down stream of the DAF. Biological treatment is typically used to further reduce the organics (BOD and COD) and nutrients (Nitrogen and Phosphorous) which can be a requirement for discharge, economically viable based on trade waste costs, or as a precursor to enable recycling wastewater back to the processing plant.

Often MBBR processes are effective due to their compact nature, although alternative aerobic or anaerobic treatment processes can be suitable depending on the water quality required.

An MBBR is a suitable biological process to further reduce the organics and nutrients in meat processing wastewater when required

Rural facilities offer more opportunities to incorporate sustainable anaerobic treatment processes that generate energy from wastewater.

Hydroflux will design the most suitable process from a comprehensive portfolio of primary treatment equipment followed by pond or tank based aerobic or anaerobic treatment plants configured to meet the tightest nutrient discharge limits or to enable potable or non-potable reuse.

The following diagram shows a typical wastewater treatment process for rural sites that Hydroflux has the skills and experience to design and construct.

Hydroflux has a wealth of experience in the design and construction of wastewater treatment systems and Advanced Water Treatment Plants that convert wastewater into potable water for the meat industry. We have worked with many state and federal regulators such as Food Safe Australia and The EPA, and fully understand the regulations pertaining to the discharge or reuse of non potable and potable water.

Hydroflux has a wealth of experience in the design and construction of wastewater treatment systems and Advanced Water Treatment Plants that convert wastewater into potable water for the meat industry. We have worked with many state and federal regulators such as Food Safe Australia and The EPA, and fully understand the regulations pertaining to the discharge or reuse of non potable and potable water.

Anaerobic treatment

Anaerobic treatment in the form of Covered Anaerobic Ponds (CALs) are an ideal solution to reduce the concentration of organic material in the wastewater whilst allowing the opportunity to generate biogas. CALs are best suited to large flow and organic loads such as those found at rendering facilities.

Hydroflux design and construct a range of anaerobic ponds and the associated biogas handling equipment to supplement the natural gas supply to boilers or for creating electricity via Cogen plants.

A Covered Anaerobic Lagoon is an ideal process for regional meat processing plants. Photo shows a Covered Anaerobic Lagoon during construction by Hydroflux at a meat processing plant in SA.

Aerobic Treatment

To achieve a water quality that is suitable for irrigation or discharge to the environment, or if wastewater is to be reused, aerobic treatment is required. Hydroflux has a comprehensive range of aerobic treatment processes designed for the efficient removal of organics and nutrients. These designs include: SBRs, MBBRs, MBRs, or activated sludge plants, all of which can be configured in above ground tanks or in lagoons.

Hydroflux has access to one the most efficient fine bubble diffuser systems in the Aerostrip which reduces the power consumption for aerobic treatment by over 50% compared to conventional methods. Aerostrip fine bubble diffusers can be incorporated into tanks or lagoons.

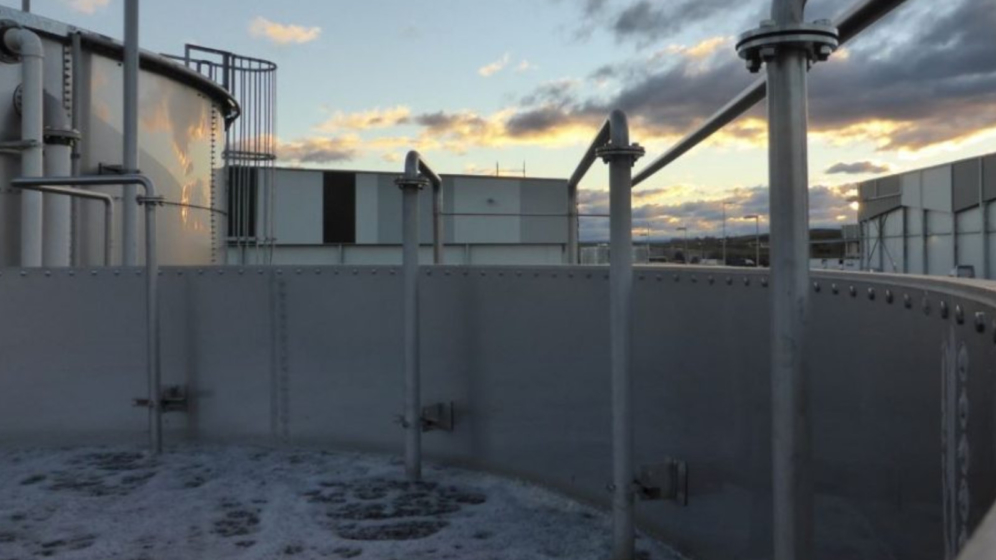

Fine bubble diffusers offer considerable power savings over surface aeration and can be installed in lagoons or tanks. The above photo shows Aerostrip fine bubble diffusers being installed in an SBR at a rendering facility.

Sludge handling

Handling of waste activated sludge is an integral component of an aerobic wastewater treatment plant. Hydroflux has vast experience in the dewatering of primary and secondary sludges using centrifuges, belt presses and screw presses.

The popularity of screw press has increased exponentially with recent advances in screw press design and are now favoured by municipalities and industry alike. One of the main benefits of the screw press is its ability to handle large volumes of dilute WAS (2000 – 3000 mg/L) directly from an aeration tank without the need for a pre-thickening stage.

Screw presses being used to dewater waste activated sludge directly from an SBR during the aeration cycle providing a very consistent feed and performance.

Process water treatment

The New Zealand red meat industry is a global leader in the supply of sustainable produce. Through continuous innovation, the red meat industry is seeing significant reduction in water usage as well as energy consumption and greenhouse gas emissions. The industry has significantly reduced its water footprint, driving efficiencies to reduce water consumption. The red meat industry is also well placed to implement further savings through the utilisation of advanced water to reduce reliance on local freshwater supplies. Efficient water solutions are critical for the red meat industry’s goal to ensure long term sustainable growth, particularly in regional and remote areas where many processors are located. Hydroflux, as a leader in this field is well placed to support the continued sustainable growth of the red meat industry.

Hydroflux Solutions

Hydroflux have a range of proven, highly efficient process and advanced water solutions for the red meat industry, including:

- Bore water treatment systems

- Surface water treatment systems

- Media Filtration & Activated carbon filtration

- UV sterilisation

- Ultrafiltration

- Reverse Osmosis

- Softening/Ion Exchange

- Electrodeionization

Hydroflux have a range of proven, highly efficient process and advanced water solutions for the red meat industry

Advanced Water treatment

Advanced Water Treatment is the treatment of wastewater for direct potable use. Hydroflux engineers pioneered Advanced Water Treatment in the meat industry in the early 2000’s. Hydroflux continues to be at the forefront of Advanced Water Treatment and recycling technology and are investing in research into the treatment and recovery of salts so that in the future, and in particular, rural facilities and their communities will reap the benefits of Advanced Water Treatment.

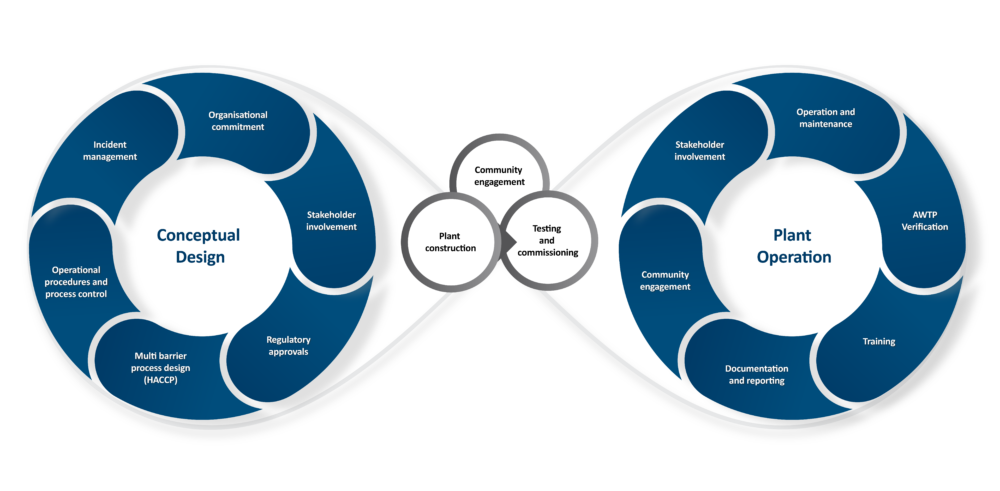

Although an AWTP utilises a series of conventional wastewater and water treatment technologies such as Ultra Filtration , Reverse Osmosis and disinfection that can be applied down stream of a n aerobic biological plant, the main features of an AWTP are the implementation of 1), a multibarrier approach and 2), establishing a suitable and acceptable risk management plan.

The diagram below shows the relationship of framework elements for a recycled water management system that Hydroflux can provide including the design, construction and operation of the AWTP.

Source: NSW Guidance for Recycled Water Management systems – Department of Primary Industries Office of Water. May 2015

The processes required to embark on an AWTP project are not insignificant so working with a company that has a proven track record is essential. As well as having the experience and skills to design and construct an Advanced Water Treatment Plant, Hydroflux will also work with you to develop the risk management plan and obtain approvals from all stake holders prior to construction.

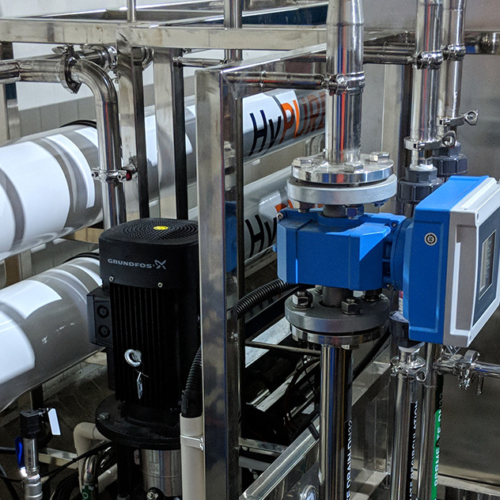

A 250kLD process water treatment plant constructed by Hydroflux incorporating a HyPURE MMF and RO systems

A 250kLD process water treatment plant constructed by Hydroflux incorporating a HyPURE MMF and RO systems

Design and construct solutions for Process and Advanced Water Treatment

As a specialist water treatment and wastewater specialist, our team are uniquely placed to offer complete support for all water services. We understand how process water management impacts on wastewater costs and vice versa. Procurement of water and wastewater projects through a single contractor offers customers significant benefits in terms of management of process risk, as well as cost savings in project delivery, through consolidated design, project management, site supervision and commissioning.

Hydroflux HyPURE RO systems are integral components of an Advanced Water Treatment Plant

Hydroflux employs qualified civil, mechanical, chemical and electrical engineers plus a team of experienced project managers, site supervisors, commissioning engineers and service technicians based in offices in most capital cities providing a local presence throughout the duration of the project.

All projects are conducted under externally approved occupational health and safety, and environmental management systems.

Hydroflux is Australia’s first Water-tech company to achieve Climate Active certifications which means his means you are engaging with a carbon neutral organisation without increasing your carbon footprint and you are supporting positive and verified action on climate change.

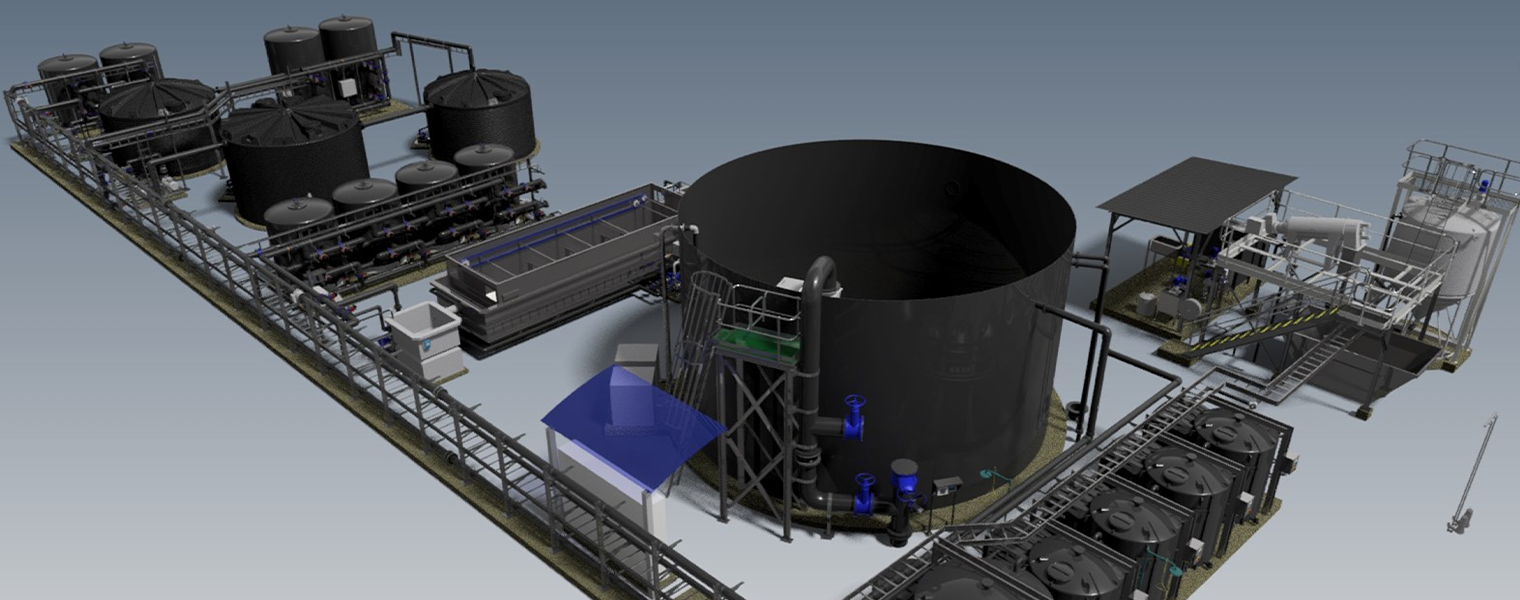

Construction of a turnkey wastewater treatment plant at a new food production facility in SA

Hydroflux can complete all the following works in house which are typically required to construct a process water or wastewater treatment plant

- Process design, development of PID’s and HAZOPS reviews

- Establishment of the most suitable treatment plant layout

- Equipment and component selection

- Civil and building designs including preparation of documentation for council or other regulators

- Electrical design and programming

- Project management and site supervision

- Environmental / Occupational health and safety plans and report

- Quality assurance plans

- Earthworks, civil works, building works, mechanical and electrical installation

- Commissioning, training and documentation as required.

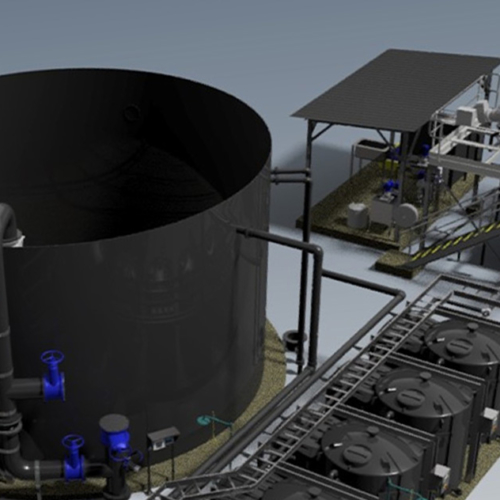

Typical Hydroflux wastewater treatment plant modelling

The utilities division provides the link to integrating the Hydroflux® businesses by providing a comprehensive support network for customers throughout New Zealand.

Hydroflux Utilities provides virtually any form of wastewater management programs including:

Chemical optimisation

Hydroflux has a comprehensive range of coagulants, antiscalants, acids/alkalis, oxidizing/reducing agents and other chemicals suitable for conditioning process water feed prior to and after treatment. We also offer a range of proprietary cleaning and sanitizing agents. Our chemists work hand in hand with the project delivery team to develop the most appropriate chemical program tailored specifically to individual sites needs.

Preventative maintenance and service

Our engineers and technicians will discuss service and maintenance programs with you during construction of the treatment plant so that you can be assured that the system will perform consistently from day one. There are many types of programs available from routine preventative maintenance, periodic

service and overhauls, to complete plant operation. Our technicians are available 24/7 to attend to unforeseen breakdowns.

Biological plant modelling

Hydroflux designs, operates and maintains biological wastewater treatment plants and we are familiar with the many causes of failure and malfunction. Via routine site attendance or online remote monitoring of the biological operating parameters, Hydroflux engineers can predict potential process issues to minimise any impact on the performance of the plant or prevent even problems from happening.

Remote monitoring

Our proprietary HyCONNECT™ remote monitoring system is installed in all our process water plants as standard, enabling instant online technical support and troubleshooting. Specialty solutions are offered for remote locations with reduced cell coverage. No matter where you are, our team of specialists are never more than a phone call away.

HyDAF

The HyDAF Dissolved Air Flotation (DAF) system’s simplicity and exceptional performance are just two of the reasons why the HyDAF…

Biological Treatment

Biological treatment can treat wastewater to achieve very low levels of organics and nutrients. When aerobic treatment processes are incorporated…