Clarifiers

Hydroflux is proud to be Australia’s first water treatment and technology company to achieve Climate Active carbon neutral certification for our entire organization. As part of our climate change mission, we continue to research, develop and invest in sustainable technologies.

Now our journey continues – our main range of water technology and associated chemical products are Climate Active certified as carbon neutral. To read more on our journey, click HERE

Hydroflux has designed, manufactured and installed or refurbished hundreds of clarifiers since 1962, and our industrial, road construction, tunneling and mining clients have come to rely on our proven design for this critical component in their treatment process.

For municipal sewage clarifier applications please visit our sister company’s website Hydroflux Epco.

The Hydroflux Epco clarifier range includes the following configurations:

- Full and half bridge fixed

- Full and half bridge peripheral drive

- LogMax® Log spiral scraper mechanisms

- VeeMax® Chevron type fixed scrapers

- HeadMax® Suction headers

Find out more

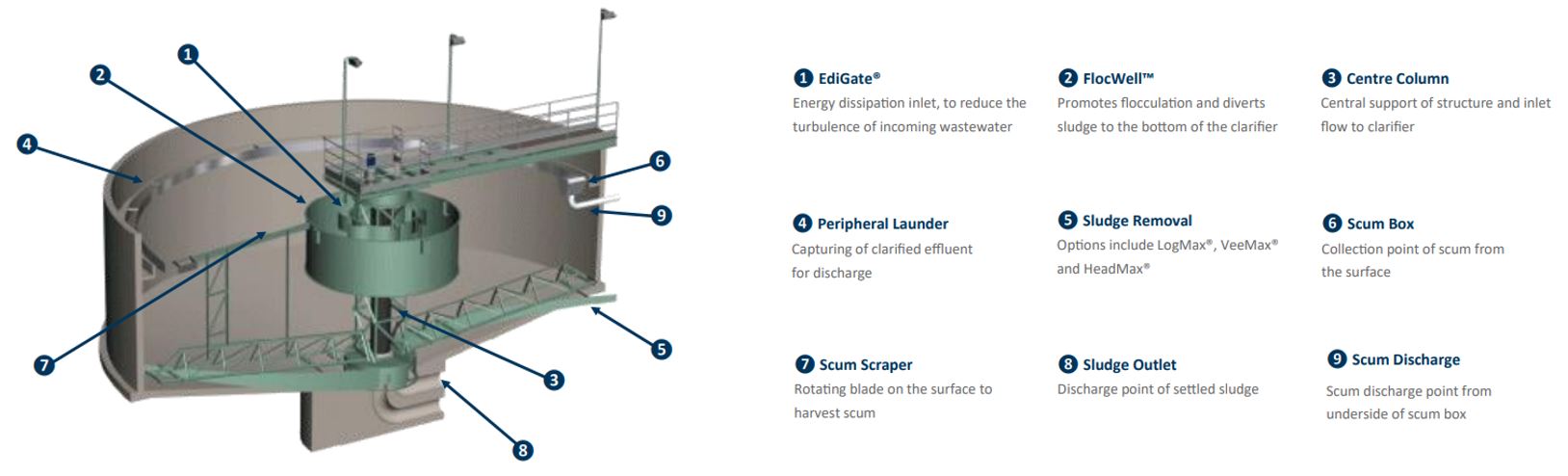

All Hydroflux Clarifiers are designed for the specific application. The diagram below shows some of the standard and more common features of a half bridge unit

The Hydroflux Epco clarifier range includes the following configurations:

Solids contact clarifiers

Hydroflux Epco offer Solids Contact Clarifiers for applications where the incoming solids load is low, or the chemical flocc is fragile, or a lower footprint is required.

The incoming flow is mixed with solids that have already settled to within the sludge blanket, via a draft tube fitted with in an impellor. This recirculation of a settled solids with incoming flow results in less chemical usage, enhanced sedimentation and a reduction in footprint.

Hydroflux Epco have extensive expertise and references on secondary clarifiers as follows:

- Over 330 clarifier systems manufactured since 1962, numerous operational as solids contact clarifiers.

- Robust construction with proven sludge removal systems (VeeMax®, LogMax® and HeadMax®).

- Proven bridge construction.

- Elimination of dead zones.

- Efficient mixing and recirculation via a low shear radial impellor.

- Free standing design in steel construction.

Lime Saturators

The lime saturator is a process unit, designed to make saturated lime water for control of the pH and alkalinity of water in the Water Treatment Plant.

The unit consists of a saturator-clarifier tank and weirs, a hopper, and a sludge rake. The unit includes an inlet and outlet, lime recirculation and slurry dosing, and spent lime solids sludge wasting. Sampling points are also provided.

Hydroflux Epco have extensive expertise and references for Lime Saturators/Clarifiers as follows:

- Over 330 clarifier systems manufactured since 1962, numerous operational in lime saturator applications.

- Robust construction with proven sludge removal systems (VeeMax®, LogMax® and HeadMax®)

Specifications

In general, Hydroflux clarifiers are fabricated with wetted parts from stainless steel, and the bridge and general fabrication steel work above water line in grade 250 mild steel epoxy coated.

The following table summarises the major components and their most common material selection. Variations on the material specifications can be made, please consult Hydroflux Epco for further detail.

| SECTION | SPECIFICATION |

| Centre Column | Rolled painted mild steel |

| Bridge | Painted mild steel |

| EdiGate® | Stainless structure with hinged doors |

| FlocWell™ | Stainless structure with HDPE sheeting |

| Scraper System | Stainless steel 304/316 |

| Squeegees | Neoprene |

| Scum Box | Stainless steel 304/316 |

| V-Notch weirs and baffles | Stainless steel 304/316 |

| CoverSweep® | Fibreglass, Aluminium or Stainless steel |

| Wheels | UHWMPE with or without metal hubs |

Hydroflux Clarifiers are available with a range of proven sludge removal systems to suit a wide variety of physical and process applications.

The LogMax® logarithmic sludge plow is designed for collection of lighter suspended sludges.

While optimum angle is approximately 30° at a tip speed of 3m per minute, the Hydroflux Epco LogMax® has an effective logarithmic angle range of between 15° and 45° and can travel at tip speeds up to 10m per minute.

The LogMax® hinge system allows each blade to be adjusted individually during installation for peak plow performance and reduced tank floor wear.

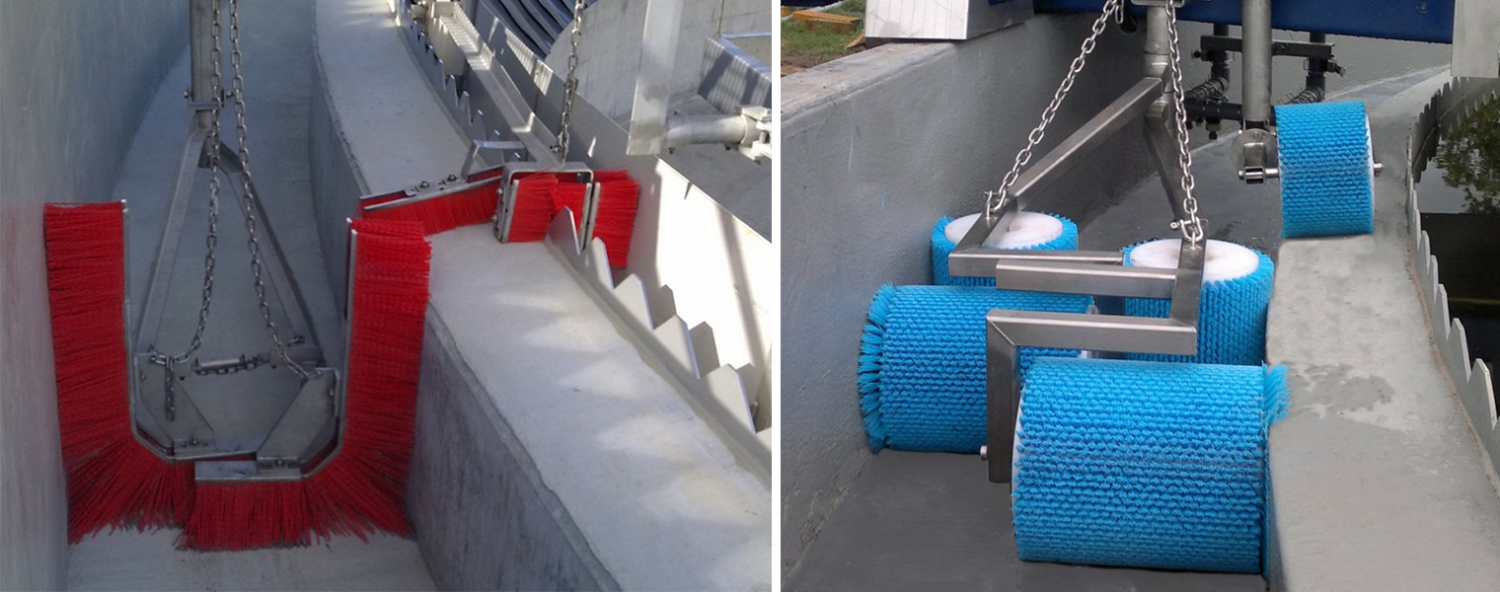

Hydroflux Clarifiers are available with a range of proven sludge removal systems to suit a wide variety of physical and process applications.

The VeeMax® Chevron pattern sludge plow is designed for heavy, relatively viscous, sludges such as those in water treatment where flocculants are added or lime is settled.

The VeeMax® Chevron pattern, available in duplex or simplex configuration, plows furrows of sludge progressively toward the sludge hopper at an average tip speed of 3m per minute.

The VeeMax® sludge plow can be readily adapted to sludge thickening with the addition of the picket fence module.

Features:

- Typically used for clarifiers under 20M

- Ideal for high sludge loading applications

- Mounting bar is suspended and adjustable from bridge

- No contact with the floor, less wear

- Low load on center column bearing

- No rollers required to support scraper blades

- Fully adjustable squeegees

- Easily replaceable squeegees

Hydroflux Clarifiers are available with a range of proven sludge removal systems to suit a wide variety of physical and process applications.

The HeadMax® hydraulic suction system is designed for sludge removal in activated sludge treatment with partial or complete nitrification processes. It allows for the construction of a flat floor which saves on civil costs associated with the clarifier build.

The HeadMax® suction system ensures rapid sludge removal and lower sludge blanket depth, reducing the potential of sludge rising up into the effluent discharge weir. The HeadMax® suction system is available in both header and tube configurations.

For maximum ongoing process control, Hydroflux recommend our suction tube configuration complete with adjustable flow gates located on the peripheral drive bridge for ease of operator access.

Hydroflux Clarifiers are available with a range of options to suit specific applications

Scum collection and removal from clarifiers water surface can be effectively facilitated via a radial surface scum scraper with a hinged skimming mechanism and self flushing scum box.

The radial scum scraper collects scum from the water surface and directs it toward the periphery of the tank. The scum comes off the radial scraper and is caught in a dam made up of the pivoted skimmer blade, the hinged skimmer blade and the peripheral scum baffles. When the hinged skimmer proceeds up onto the scum box the trapped scum is dumped through the scum box.

The scum box outlet pipe is equipped with a mechanically activated reflux valve which has an extension arm fitted to the valve flap spindle. As the bridge passes over the scum box, an actuating angle mounted under the bridge opens the scum valve by striking an extension of the valve spindle. This allows the collected scum along with a quantity of settled effluent to be flushed through and exit the tank.

The inside of the peripheral scum baffle is wiped continuously every revolution, by a rubber wiper attached to the hinged skimmer.

Stamford Baffles

Hydroflux Epco can provide Stamford baffles below the launder system. These baffles eliminate density current flows that can disturb sedimentation of the sludge floccs by moving then away from the launder and towards the centre of the clarifier tank. It also prevents sludge from rising up into the launder system.

The Stamford baffle is fixed to the wall of the clarifier just below the launder. It slopes downwards at an angle and extends towards the centre of the clarifier.

The system comprises of:

- An array of GR316 stainless steel brackets

- HDPE baffles plates secured to the brackets using stainless fasteners

The Stamford baffle array is mounted to the civil work of the clarifier tank via stainless threaded rod drilled and secured into place using a polyester resin design for use in submerged environments.

Launder Covers

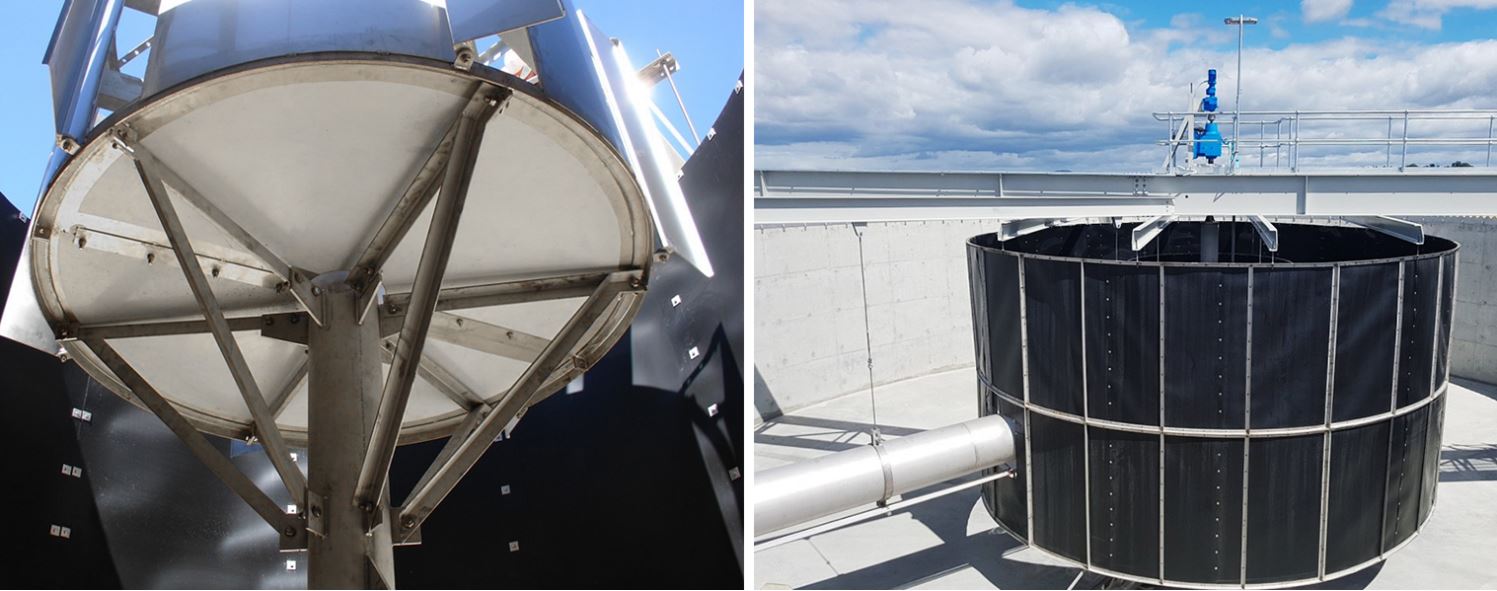

The CoverSweep® launder covers eliminate problems associated with excess algal growth in clarifier launders.

The CoverSweep® system is a series of interlocking fibreglass or stainless steel hatches allowing access to the entire trough if required, yet all the while blocking 100% of sunlight across the launder trough, effluent weirs and scum baffle.

The major benefit of CoverSweep® launder covers is the removal of troublesome launder maintenance such as chlorination or effluent spray systems. The significant improvement to OPEX costs is the reduction in down stream pump maintenance related to algae blockage.

CleanSweep

The CleanSweep® roller brush combats the Algae problem in clarifier launders head on.

The CleanSweep® approach divides the launder trough in to five zones with a dedicated roller constantly cleaning each zone.

Combining a unique bristle design with a retarding rotational force acting directly on algal growth, Hydroflux Epco have designed a system that keeps operators out of the trough, reduces the need for launder sprays and does away with adhoc homemade alternatives that are less effective.

EdiGate

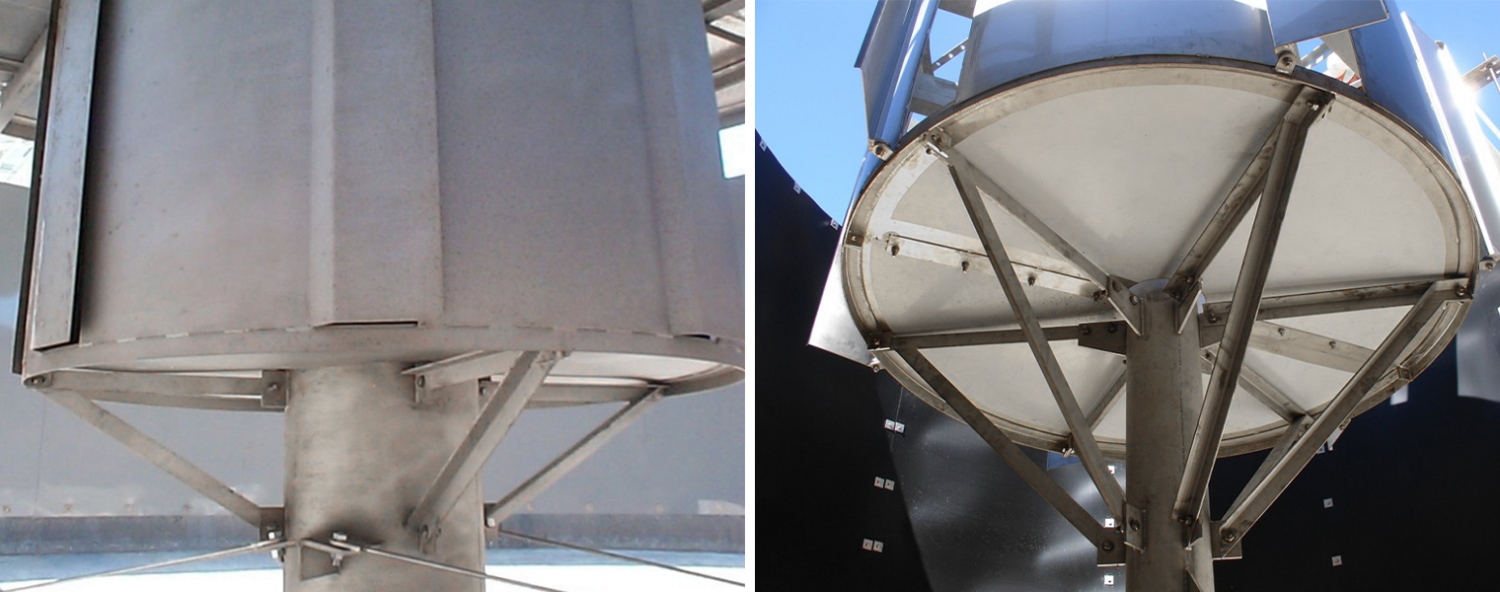

EdiGate® is specifically designed to eliminate the need for mechanical mixing in the flocculation zone of clarifier feed wells.

Available in both fixed gate and hinged gate designs the EdiGate® energy dissipation inlet feedwell flocculation system reduces jetting of incoming liquor through its tangential flat gate design.

In the larger designs the EdiGate® is provided as a double gate arrangement at each discharge port to increase interference of flow from neighbouring ports which in turn improves the settling rate of flocculated sludge.

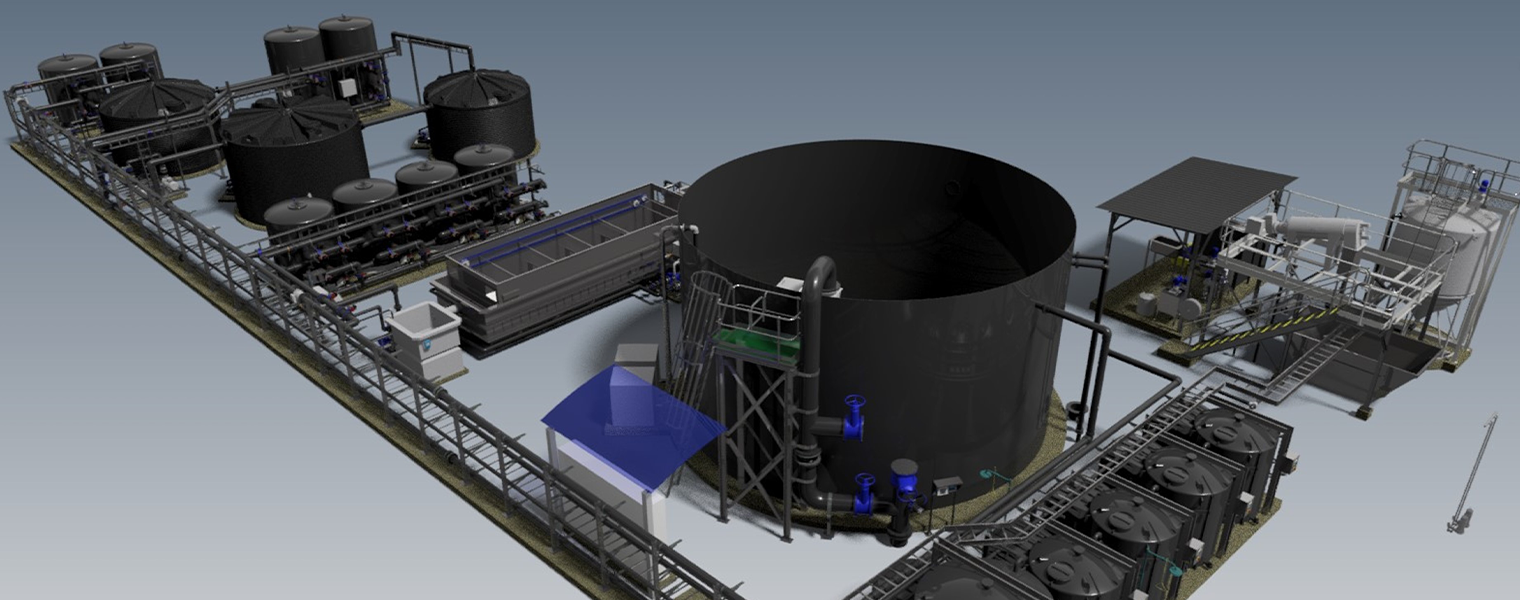

The Hydroflux Clarifier is just one process component in complete water or wastewater treatment plant and is usually supported by a range of ancillary process operations to condition the influent, handle the sludge generated, or provide further treatment or recycling. Hydroflux has the skills and expertise to conduct any design and construct project incorporating a Lamella Separator. Hydroflux employs qualified civil, mechanical, chemical and electrical engineers plus a team of experienced project managers, site supervisors, commissioning engineers and service technicians based in offices throughout Australia providing a local presence throughout the duration of the project.

All projects are conducted under externally approved occupational health and safety, and environmental management systems.

Hydroflux design and construct complete wastewater treatment systems involving clarification technology.

Hydroflux is Australia’s first Water-tech company to achieve Climate Active certifications which means by engaging with Hydroflux you are supporting positive and verified action on climate change.

Construction of a turnkey wastewater treatment plant at a new food production facility in SA

Construction of a turnkey wastewater treatment plant at a new food production facility in SA

The Utilities division provides the link to integrating the Hydroflux® businesses by providing a comprehensive support network for customers throughout Australia.

Hydroflux Utilities provides virtually any form of wastewater management programs including:

Chemical optimisation

Hydroflux has a comprehensive range of coagulants and flocculants suitable for conditioning wastewater or sludge. The most appropriate chemical program will be determined before commissioning based on experience, or test work if possible, and long-term cost-effective chemical supply contracts can be arranged.

Preventative maintenance and service

Our engineers and technicians will discuss service and maintenance programs with you during construction of the wastewater treatment plant so that you can be assured that the system will perform consistently from day 1. There are many types of programs available from routine preventative maintenance, periodic service and overhauls, to complete plant operation. Our technicians are available 24/7 to attend to unforeseen breakdowns.