HySmart SBR – Sequencing Batch Reactors

Sequencing Batch Reactors (SBRs) Using HySMART® Technology

SBRs are an advanced form of the activated sludge process, specifically designed for high-performance wastewater treatment in industrial applications. Hydroflux has extensive experience in implementing SBRs across the Food and Beverage sector, as well as various general manufacturing processes, ensuring efficient and reliable treatment solutions.

Unlike continuous-flow aerobic biological systems, SBRs operate in a batch mode, allowing for enhanced process control and operational flexibility. This batch operation enables precise management of treatment cycles, optimising organic load reduction and nutrient removal.

Please browse the photo gallery below for examples of SBRs designed and constructed by Hydroflux.

Some of the main benefits of Sequencing Batch Reactors are:

Space Efficiency – Eliminates the need for separate aeration and sedimentation tanks, reducing footprint requirements.

Flexibility in Operation – Can handle variable flow and load conditions, making it ideal for fluctuating wastewater volumes, whilst an adjustable cycle time allows customisation for specific treatment needs.

Effective Nutrient Removal – Can easily be configured to efficiently remove organic matter as well as nitrogen and phosphorus to very low levels.

Automated and Easy to Control – Advanced control systems allow for automated monitoring and operation, minimising manual intervention.

How the Sequencing Batch Reactors Works

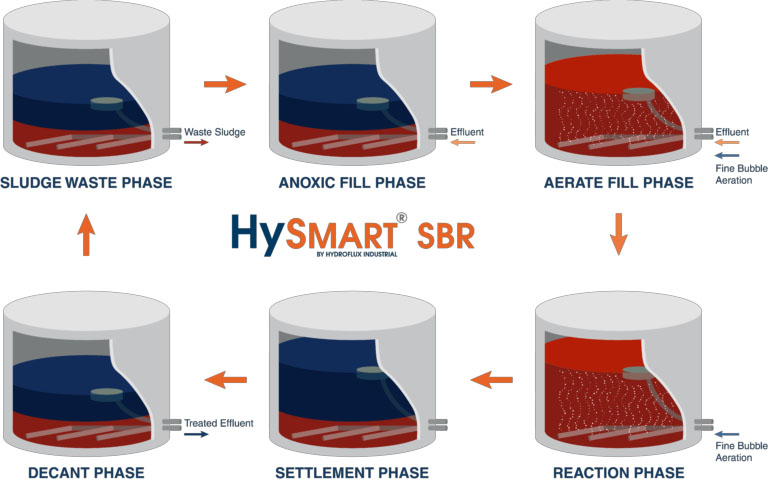

The HySmart SBR is uniquely designed to perform all essential biological treatment stages—anoxic, aerobic, and biomass separation – within a single vessel. This integrated approach eliminates the need for separate treatment tanks, reducing footprint requirements and simplifying plant design. There are six Phases to the HySmart SBR treatment system as shown in the diagram below:

The sequencing and timing of these phases can be adjusted based on Influent wastewater composition (organic load, nitrogen, phosphorus levels) and the required discharge limits.

| Phase | In the settlement phase, biomass is settled in the reactor so that a clear supernatant can be decanted from the top of the SBR | |

|---|---|---|

| 1 | Anoxic Fill Phase | In the settlement phase, biomass is settled in the reactor so that a clear supernatant can be decanted from the top of the SBR |

| 2 | Aeration Fill Phase | Filling continues and aeration commences. The aeration phase is where oxygen is introduced into the SBR to encourage the multiplication of aerobic bacteria |

| 3 | Aeration Reaction Phase | This stage continues the multiplication of aerobic bacteria and is where the BOD is consumed |

| 4 | Settlement Phase | In the settlement phase biomass is settled in the reactor so that a clear supernatant can be decanted from the top of the SBR |

| 5 | Decant Phase | Treated wastewater is removed via a floating decanter |

| 6 | Sludge Waste Phase | Some excess biomass is removed from the reactor before the cycle starts |

The Complete Sequencing Batch Reactor Process

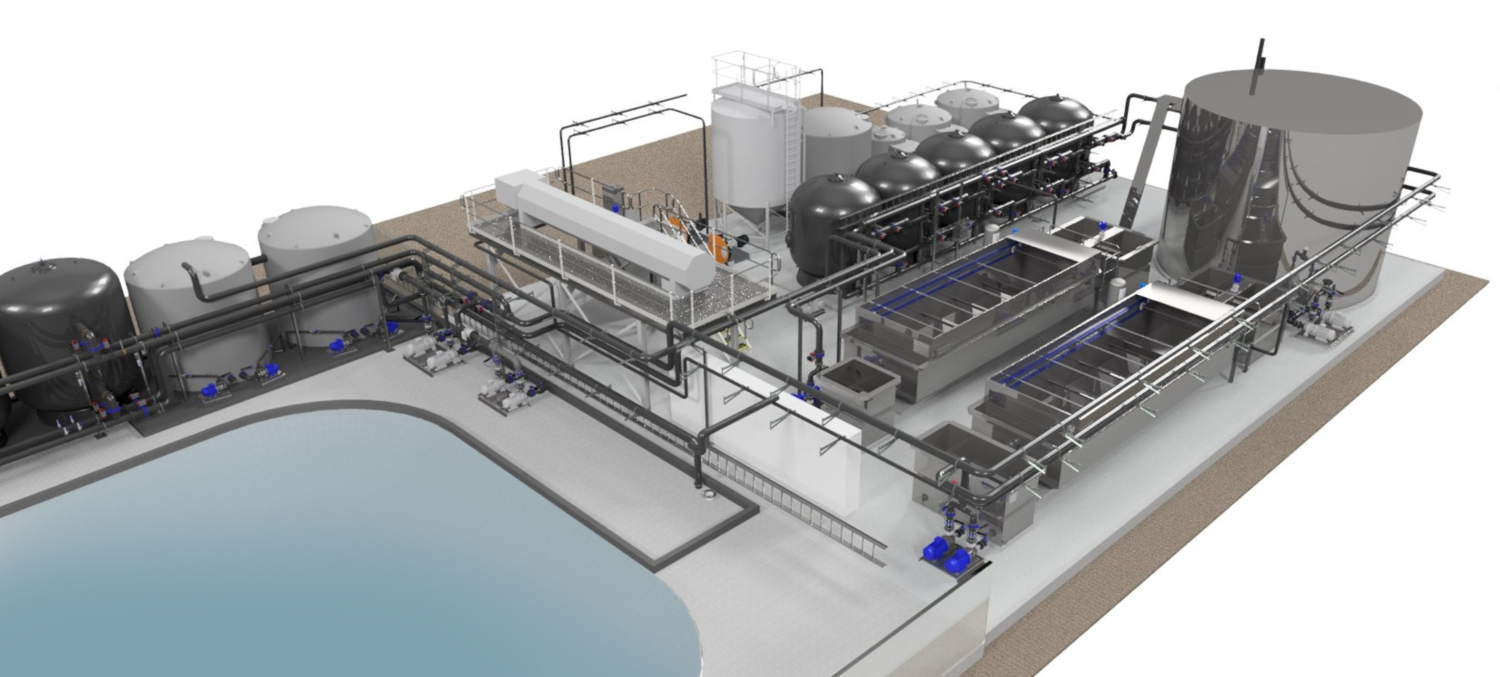

The SBR process is a highly efficient and straightforward aerobic biological treatment method. After initial flow balancing and primary treatment, where large solids, grease, and grit are removed, the wastewater is transferred into the SBR aeration tank, where the cyclic biological treatment process occurs. Once treatment is complete, the clear effluent is then discharged from the tank via a floating decanter system, ensuring that only high-quality treated water is released while preventing floating solids from escaping.

To maintain optimal Mixed Liquor Suspended Solids (MLSS) concentrations, excess sludge is periodically withdrawn from the aeration tank. This process ensures that the system maintains an adequate microbial population for continuous biological treatment. The waste sludge is then processed through a dewatering system, such as a Screw Press, to reduce its water content and minimise disposal costs. Dewatered sludge can be further treated, composted, or disposed of depending on local regulations and site-specific requirements.

The configuration of the HySMART SBR is very simple and often only requires a single aeration tank with a waste-activated sludge withdrawal system.

Sequencing Batch Reactor Aeration and Configuration

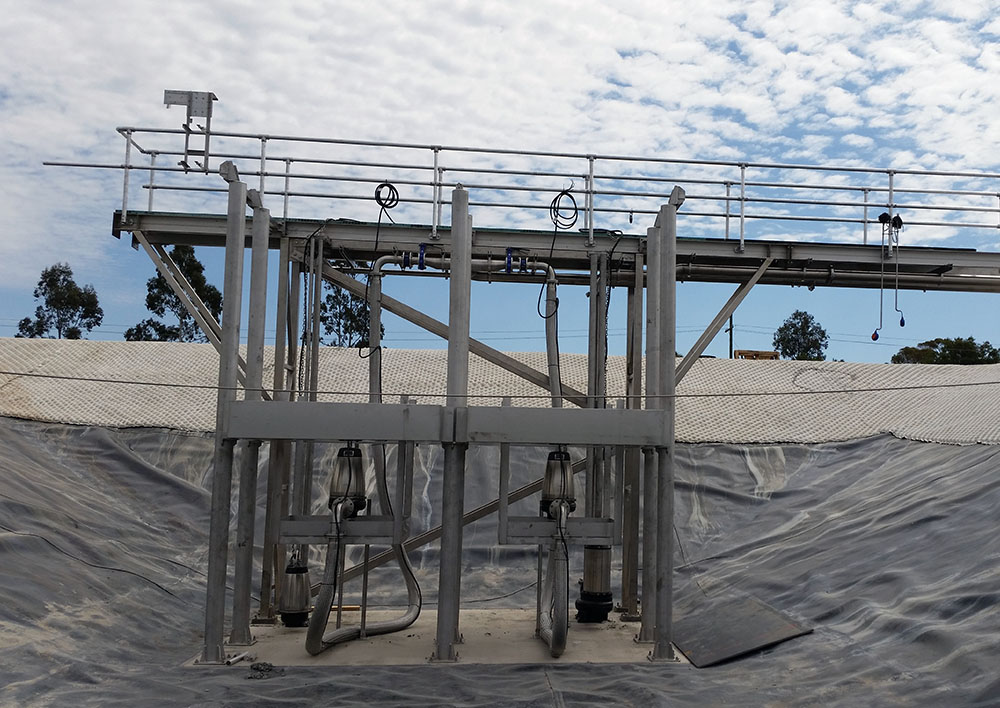

HySmart SBRs can be configured in above-ground tanks or ponds using various types of aeration methods, including fine bubble diffusers, surface aerators and submersible aerators.

Our preference is to utilise Aerostrip fine bubble diffusers where possible as they offer the most sustainable solution in terms of power demand, although the most suitable means of aeration will always depend on the size and configuration of the aeration basin and the oxygen requirements.

Sequencing Batch Reactor FAQs

Yes, a Sequencing Batch Reactor (SBR) is highly effective for treating wastewater with high nitrogen loads, thanks to its ability to precisely control biological processes. Hydroflux has successfully installed SBRs capable of handling over 1000 mg/L of total nitrogen, demonstrating their effectiveness in highly demanding applications. Higher nitrogen concentrations increase both the reactor capacity and aeration demand, which Hydroflux’s process engineers carefully model in-house to ensure optimal performance. Depending on the performance required, it is sometimes necessary to include a separate dedicated anoxic tank into the design.

While some phosphorus is naturally removed through biological uptake, higher phosphorus concentrations or stricter effluent limits may require additional chemical precipitation. This can be easily achieved in an SBR by dosing a coagulant into the aeration basin, ensuring effective phosphorus removal when needed.

No, multi-tank options can be preferable in certain situations. For example, in a twin-tank setup, while one tank is in the settlement or decant phase, another tank can be in the filling or aeration phase. This out-of-sequence phasing ensures a more consistent and continuous flow into the SBR system as a whole, creating an almost continuous process similar to other biological treatment systems.

In Sequential Batch Reactors (SBRs), the selection of the aeration method is influenced by factors such as the size of the aeration tank, energy efficiency, oxygen demand, and maintenance requirements. Fine bubble diffusers are the most widely used due to their high oxygen transfer efficiency, making them ideal for handling high organic loads in larger SBR systems. In these cases, Hydroflux’s preference for fine bubble diffusers is the highly efficient Aerostrip fine bubble diffusers. In contrast, surface aeration can be an effective solution for treatment ponds or areas where installing diffusers is either difficult or not feasible.

Another viable option is submersible aerators, which are often more compact and easier to install and maintain compared to surface aerators or fine bubble diffusers. These aerators are commonly used in smaller applications or situations where space is limited.

The optimal choice depends on the specific treatment goals, the design of the tank or aeration basin, and the operational requirements, and the decision should be tailored to the unique needs of the system.

A major challenge with Sequencing Batch Reactor (SBR) systems is poor sludge settling. Poor sludge settling, often caused by filamentous bacteria overgrowth, can lead to high total suspended solids (TSS) in the effluent and reduced treatment efficiency. Since SBRs do not have a dedicated clarifier like conventional activated sludge systems, bulking sludge can be more problematic, making it difficult to achieve clear separation between treated water and biomass. A HyDAF dissolved air flotation system or post filtration systems such as MMF are sometimes uses as a safeguard against solids carry over in SBRs.

Additionally, sludge wastage must be carefully controlled to maintain optimal biomass levels. If the sludge retention time (SRT) is too high, older sludge can degrade, leading to foaming, odors, and poor treatment performance. To prevent these issues, operators must closely monitor the sludge volume index (SVI) and adjust sludge wasting strategies accordingly, ensuring proper sludge age and system stability.

Why Industry Chooses to Work with Hydroflux

Hydroflux can deliver complete design and construct projects that cover all stages of treatment, including primary, secondary biological, sludge handling and tertiary processes. Our systems are designed to enable high-quality discharge or water reuse, with flexible delivery models available from equipment supply to integration of full turnkey solutions.

Our team comprises qualified civil, mechanical, chemical, and electrical engineers, along with experienced project managers, site supervisors, commissioning specialists, and service technicians. To maintain long-term performance and reliability, Hydroflux also offers comprehensive servicing and maintenance contracts.

Contact us for technical discussion about how we can assist you with your wastewater treatment facility.

Sustainable Solutions

As Australia’s first certified carbon-neutral water and wastewater chemical supply and service business, we focus on sustainability. Developing and delivering sustainable solutions for treatment plant operation and maintenance is at the core of what we do. Our equipment is the most sustainable in the Australian and New Zealand markets and is not just effective but also carbon-neutral. Click here to find out what this means for you.