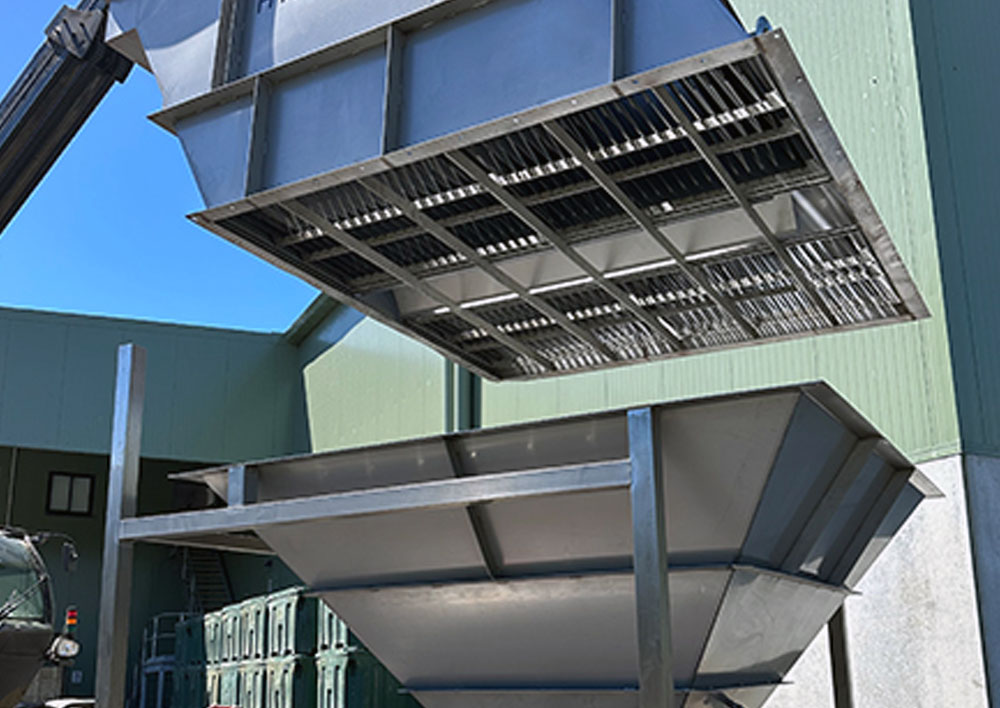

Lamella Clarifiers

Hydroflux HySEP® Lamella Clarifiers – Efficient Solid-Liquid Separation in a Very Small Footprint

Hydroflux HySEP® Lamella Clarifiers are designed for high-efficiency sedimentation, providing superior solid-liquid separation in a compact footprint. Ideal for industrial applications, our Lamella clarifier systems optimise space and performance by utilising inclined plate technology to maximise settling capacity. Our robust stainless steel construction and modular designs ensure durability and easy integration into new or existing treatment systems.

Whether for pre-treatment, primary clarification, or sludge thickening, Hydroflux Lamella clarifiers offer a cost-effective and low-maintenance solution tailored to your operational needs. Contact us today to learn how our Lamella Clarifier technology can enhance your wastewater treatment process.

HySEP Lamella Clarifiers Separator Features

- Highly effective plate pack surface area with a non-clogging crossflow lamella plate configuration

- All stainless steel lamella pack construction for chemical resistance (all grades of stainless steel available)

- Design to promote laminar flow conditions to optimise performance

- Free-standing design in steel construction or concrete for larger applications

- Standard 60-degree plate angle with 10 mm and 40 mm spacing, depending on the application

- 60-degree sludge hopper able to prevent rat-holing and improve solids removal

Sizing and Operation

Hydroflux Industrial’s HySEP Lamella Clarifiers are designed specifically for industrial wastewater treatment including Anodisers, tunnel construction, groundwater treatment, galvanising plants, general manufacturing and mining.

The HySEP Lamella Clarifier range is available in the following standard sizes:

| Model | Plate Area* | Flow Rate** |

| CS5 | 6.1m2 | 5 – 10 kL/hr |

| CS10 | 11.5m2 | 10 – 15 kL/hr |

| CS20 | 20.9m2 | 20 – 30 kL/hr |

| CS30 | 31.3m2 | 30 – 45 kL/hr |

| CS40 | 41.7m2 | 40 – 60 kL/hr |

| CS60 | 62.6m2 | 60 – 90 kL/hr |

| CS80 | 84.6m2 | 80 – 120 kL/hr |

* Plate Area projected at 60°

**Flowrate subject to application and plate spacing.

Lamella Clarifier FAQs

There is no difference between and inclined plate separator and lamella plate separator, it is just the terminology. The plate separator as the name suggests contains inclined plates that increase the effective surface area of the unit allowing treatment in a smaller footprint than a conventional clarifier.

This depends on the type of solids that are being removed and the quality of treated water required. A dose of coagulant and flocculant will certainly improve the solids separation however this is not always necessary.

The Hydroflux CS Lamella range is designed for industrial applications where high solids loads are usually experienced. The spacing between the plates is selected based on the type of solids and the solids load in the raw water to prevent blockages from occurring. That said, “sticky” types of solids can adhere to plates resulting in potential blockages in which case the conventional type of Hydroflux clarifier may be a preferable selection.

The sludge that is collected in the base of the CS Lamella is usually transferred to a dewatering process such as a filter press or screw press.

The standard settling rate use in the sizing tables to calculate the nominal flow for each model is 1 m/hr. Sizing of the units is different for every application as the required settling rate varies depending on the solids that are being removed and the pate spacing.

Why choose to work with Hydroflux Industrial?

Hydroflux’s team includes qualified civil, mechanical, chemical, and electrical engineers, as well as experienced project managers, site supervisors, commissioning engineers, and service technicians. With offices located across Australia, Hydroflux ensures a strong local presence throughout the duration of every project. All projects are carried out under externally certified occupational health and safety and environmental management systems.

Hydroflux designs and constructs comprehensive wastewater treatment systems that incorporate various types of processing equipment, including screens, physical/chemical, biological, and tertiary treatment technologies to enable high quality discharge or water reuse.

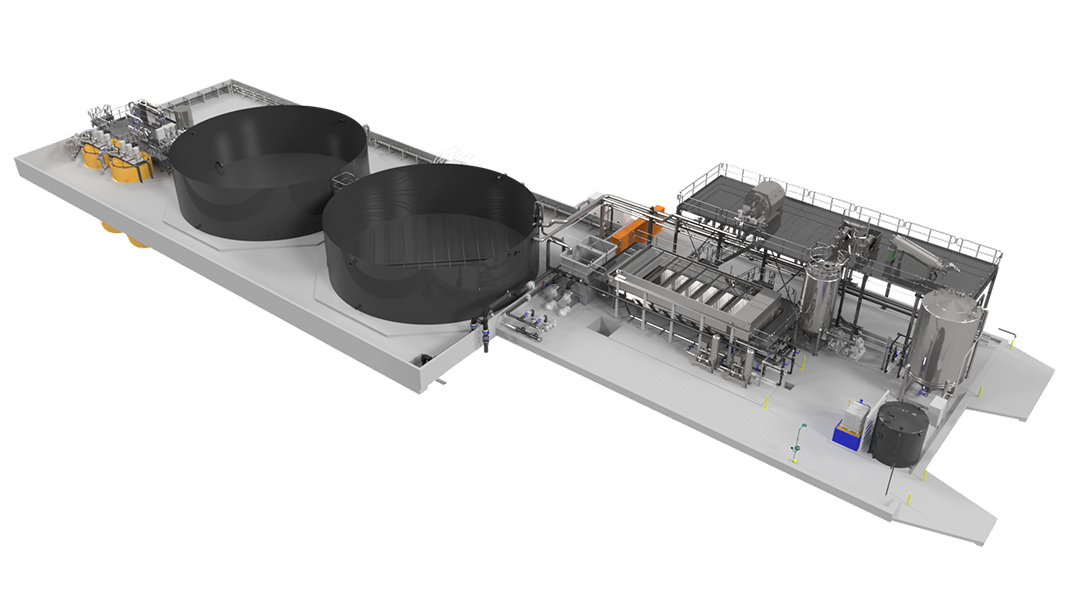

Below is a 3D drawing of a treatment plant constructed by Hydroflux that incorporated balancing, heat recovery, rotary screening, DAF, and sludge dewatering.

Contact us for a technical discussion about how we can assist you with your wastewater treatment facility.

Sustainable Solutions

As Australia’s first certified carbon-neutral water and wastewater chemical supply and service business, we focus on sustainability. Developing and delivering sustainable solutions for treatment plant operation and maintenance is at the core of what we do. Our equipment is the most sustainable in the Australian and New Zealand market and is also carbon-neutral. Click here to find out what this means for you.