Chemical Dosing Systems

Reliable Chemical Dosing and Handling Systems

At Hydroflux, we specialise in designing and supplying high-quality chemical dosing, handling and bunding for water and wastewater treatment applications. Our solutions ensure accurate dosing, enhanced treatment efficiency, and cost savings while maintaining the highest safety standards.

Our customers choose Hydroflux for several reasons:

Precision & Reliability

Our dosing systems use high-accuracy metering pumps and advanced control technology to ensure consistent chemical dosing for optimal process performance.

Versatile & Customisable

Designed to handle a wide range of coagulants, flocculants, acids, alkalis, and other treatment chemicals.

Safety & Compliance

We prioritise operator safety and environmental compliance with features like spill containment, automated controls, and leak-detection systems.

Hydroflux has vast experience in the design and construction of chemical storage and dosing facilities, including:

- Bulk chemical storage plus a range of IBC bunds, dosing systems and level control options

- Various types of dosing pumps and control systems

- Automated pH probe washing

- Automated polymer blending and dosing equipment for emulsion or powdered polymers

- Integrated back-to-base alarms

Hydroflux Chemical Bunding for Bulk and IBC Storage

Hydroflux provides robust and compliant chemical bunding solutions designed for the safe storage of bulk chemicals and Intermediate Bulk Containers (IBCs) in industrial and water treatment applications. Our bunding systems ensure environmental protection, spill containment, and regulatory compliance, minimising risks associated with chemical handling and storage.

Why is Chemical Bunding Important?

Prevents Spills & Leaks – Containment bunds act as a secondary barrier to prevent hazardous chemicals from escaping into the environment.

Ensures Compliance – Meets New Zealand and international workplace health & safety (WHS) and environmental protection regulations.

Protects Equipment & Personnel – Reduces risks associated with chemical exposure, fire hazards, and workplace contamination.

Customizable & Scalable – Available in various sizes and configurations to accommodate bulk storage tanks, IBCs, and smaller chemical containers.

Hydroflux Chemical Bunding Solutions

1. Bunding for BULK Chemical Storage

- Hydroflux designs bunds for large-volume chemical storage tanks, ensuring compliance with AS 3780 and EPA guidelines

- Heavy-duty bunded containment areas or self-bunded tanks for acids, alkalis, coagulants, flocculants, and other treatment chemicals

- Constructed from corrosion-resistant materials – Stainless steel, HDPE, concrete, or specialised chemical-resistant coatings

- Integrated drain systems for controlled liquid removal and spill management

- Custom designs available to match specific site requirements

2. Bunding for IBC Chemical Storage

Intermediate Bulk Containers (IBCs) are widely used for transport and on-site storage of liquid chemicals. Hydroflux offers bunding solutions to safely store and manage IBCs in compliance with spill containment regulations.

- IBC Spill Pallets – Heavy-duty platforms with integrated bunding, suitable for single or multiple IBCs

- Stackable & Modular Bunding – Scalable designs to accommodate increasing chemical storage needs

- HDPE and Polyethylene Construction – Resistant to harsh chemicals, ensuring long-term durability

- Custom Drainage & Sumps – Allows for easy cleanup and spill recovery

Compliance and Safety Standards

Hydroflux bunding solutions comply with:

- Australian and New Zealand Standards (AS 3780, AS 1940, AS/NZS 4452)

- EPA Environmental Protection Guidelines

- Workplace Health & Safety (WHS) Regulations

Hydroflux offers custom-designed bunding systems to meet your specific chemical storage requirements. Contact us today to discuss your needs.

Reliable, Efficient, and Customisable Dosing Solutions

Hydroflux designs and supplies fully integrated chemical dosing plants, including polymer dosing systems, to support a wide range of water and wastewater treatment applications. Our dosing plants are engineered for precision, automation, and safety, ensuring optimal chemical usage and treatment performance.

Accurate & Efficient Dosing – High-precision metering pumps and control systems ensure consistent dosing to optimize treatment processes

Fully Automated Operation – PLC and SCADA-compatible systems allow for remote monitoring and automated chemical dosing based on real-time process conditions

Modular & Scalable Design – Custom-built to meet specific site requirements, from small batch dosing systems to large-scale continuous dosing plants

Safe & Compliant – Designed to meet safety standards, WHS and EPA regulations with spill containment, leak detection, and chemical-resistant materials

Multiple Chemical Compatibility – Suitable for a wide range of treatment chemicals, including:

- Coagulants & Flocculants

- pH Adjusters (Acids & Alkalis)

- Disinfectants & Oxidants

- Polymers for Sludge Dewatering

Highly Efficient Polymer Dosing Systems for Powders and Emulsions

Hydroflux Polymer Dosing Systems provide precise and automated preparation, activation, and dosing of polymers for water and wastewater treatment. Designed for both dry and liquid polymers, these systems ensure optimal flocculation, sludge dewatering, and solid-liquid separation while minimizing chemical wastage. With PLC automation, modular designs, and skid-mounted options, Hydroflux polymer dosing solutions are easy to integrate, safe to operate, and built for efficiency, making them ideal for any industrial application.

Dry Polymer Preparation & Dosing Systems

- Fully automated powder polymer mixing and dosing for sludge dewatering and flocculation

- Batch or continuous operation with pre-set dosing rates

- Integrated agitators and dosing pumps for complete polymer activation

- Available in stainless steel or HDPE construction for chemical resistance

Liquid Polymer Dosing Systems

- Ideal for inline polymer dosing in wastewater and sludge treatment

- Pre-dilution and mixing units ensure uniform polymer activation

- Variable-speed dosing pumps for precise control

- Skid-mounted, plug-and-play systems for easy installation

Emulsion Polymer Systems

- Designed for viscous polymer handling, including automatic dilution and activation

- Low-shear mixing technology prevents polymer degradation

- Flow-proportional dosing for process efficiency

Why choose to work with Hydroflux Industrial?

Hydroflux’s team includes qualified civil, mechanical, chemical, and electrical engineers, as well as experienced project managers, site supervisors, commissioning engineers, and service technicians. All projects are carried out under externally certified occupational health and safety and environmental management systems.

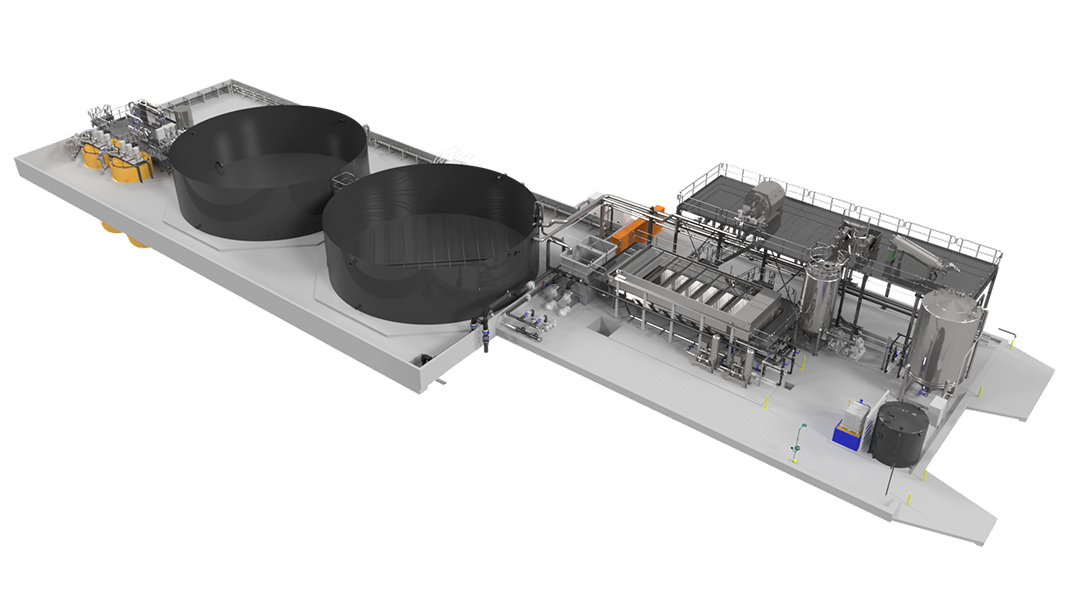

Hydroflux designs and constructs comprehensive wastewater treatment systems that incorporate various types of processing equipment, including screens, physical/chemical, biological, and tertiary treatment technologies to enable high-quality discharge or water reuse. Below is a 3D drawing of a treatment plant constructed by Hydroflux that incorporated balancing, heat recovery, rotary screening, DAF, and sludge dewatering. Contact us for a technical discussion about how we can assist you with your wastewater treatment facility.

Sustainable Solutions

As Australia’s first certified carbon-neutral water and wastewater chemical supply and service business, we focus on sustainability. Developing and delivering sustainable solutions for treatment plant operation and maintenance is at the core of what we do. Our equipment is the most sustainable in the Australian and New Zealand markets and is also carbon-neutral. Click here to find out what this means for you.