Wastewater Clarifiers

Clarifiers for Reliable Wastewater Treatment for Industry

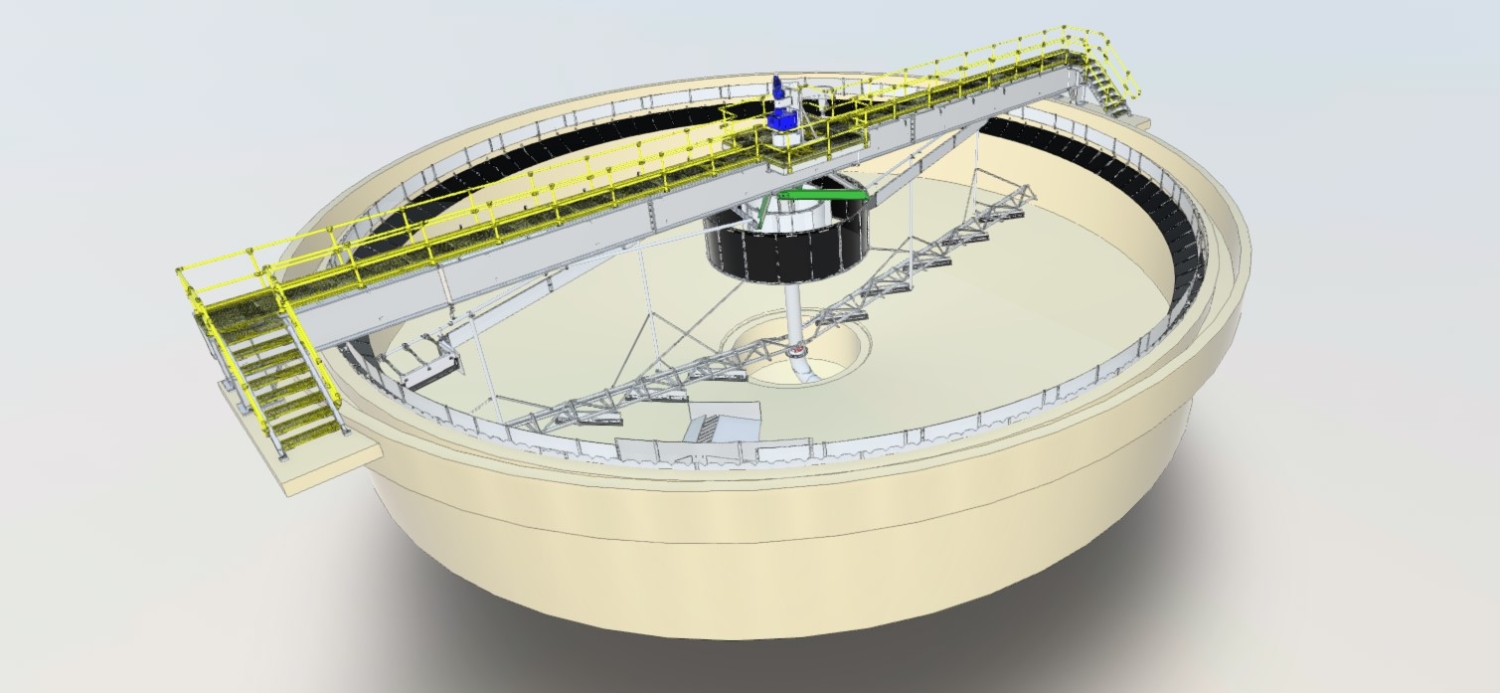

Hydroflux Epco wastewater clarifiers are reliable wastewater treatment solutions for industry. We offer full and half-bridge fixed clarifiers, full and half-bridge peripheral drive wastewater clarifiers, and advanced scraper mechanisms like LogMax® log spiral scrapers, VeeMax® chevron-type fixed scrapers, and HeadMax® suction headers.

Hydroflux has the expertise to design and deliver the most effective wastewater clarifier solution for your treatment process, ensuring efficient solids separation and reliable performance across industrial wastewater treatment and water treatment for road construction, tunneling, and the mining sector.

Hydroflux Epco have extensive expertise and references on secondary clarifiers:

- Over 330 clarifier systems manufactured since 1962

- Robust construction with proprietary sludge removal systems

- Proven bridge construction options

- Efficient mixing and recirculation via a low shear radial impellor and elimination of dead zones

- Concrete or free standing design

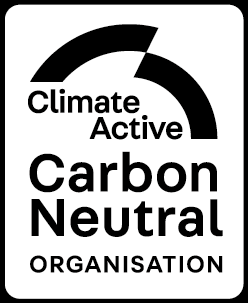

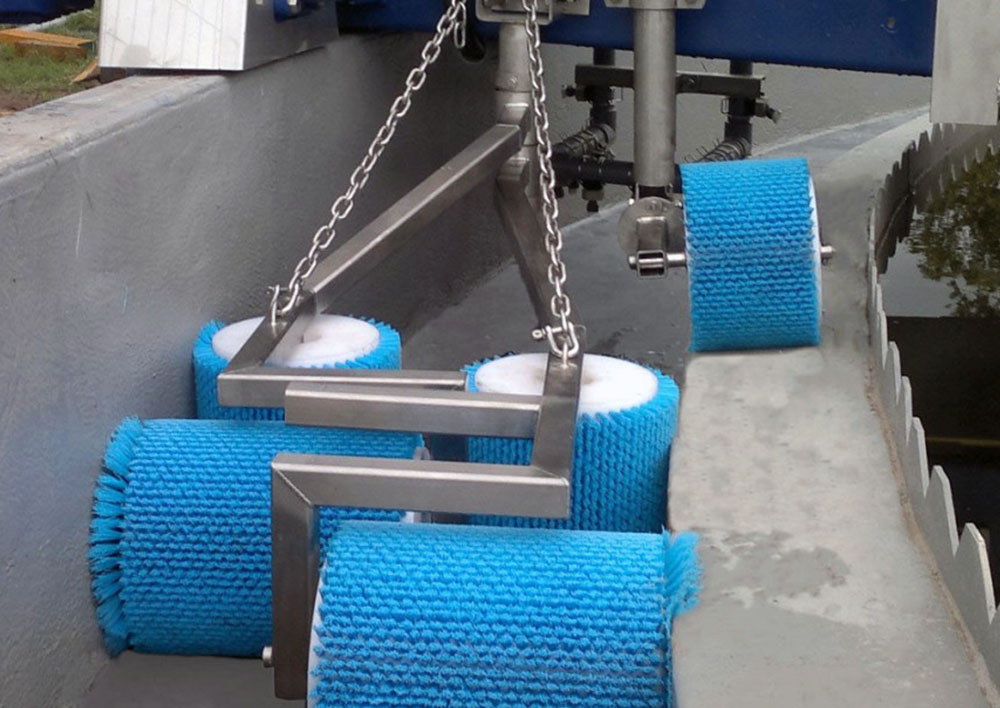

Please browse some of Hydroflux Epco’s Clarifier projects in the photo gallery below.

Wastewater Clarifier Configurations

The Hydroflux Epco wastewater clarifier range is available in sizes up to 50 meters in diameter and includes:

- Full and half-bridge fixed clarifiers

- Full and half-bridge peripheral drive clarifiers

Sludge Removal Mechanisms

Hydroflux offers three types of proprietary sludge removal systems to suit various applications

HeadMax® Hydraulic Suction System

The HeadMax hydraulic suction system is specifically designed for sludge removal in activated sludge treatment processes, including partial and complete nitrification. This system enables the construction of a flat floor, reducing civil costs associated with the clarifier build.

By ensuring rapid sludge removal and maintaining a lower sludge blanket depth, the HeadMax system minimises the risk of sludge rising into the effluent discharge weir. It is available in both header and tube configurations to suit different applications.

LogMax® Logarithmic Sludge Plow

The LogMax logarithmic sludge plow is optimised for collecting lighter suspended sludges.

- Features an adjustable logarithmic angle ranging from 15° to 45°

- Operates at tip speeds of up to 10 meters per minute, with an optimal angle of 30° at 3 meters per minute

- Individually adjustable blades for peak performance and reduced tank floor wear

VeeMax® Chevron Pattern Sludge Plow

The VeeMax Chevron pattern sludge plow is designed to handle heavy, viscous sludges, such as those treated with flocculants or settled lime.

- Available in simplex or duplex configurations

- Progressively plows sludge toward the hopper at an average tip speed of 3 meters per minute

- Can be adapted for sludge thickening with the addition of a picket fence module

Other Proprietary Wastewater Clarifier Components

Stamford Baffles: Installed below the launder system, these baffles prevent sludge disturbance by directing flow towards the clarifier center and stopping sludge from rising. Made of 316 stainless steel brackets and HDPE baffle plates, they are secured with stainless fasteners and polyester resin anchors for submerged conditions.

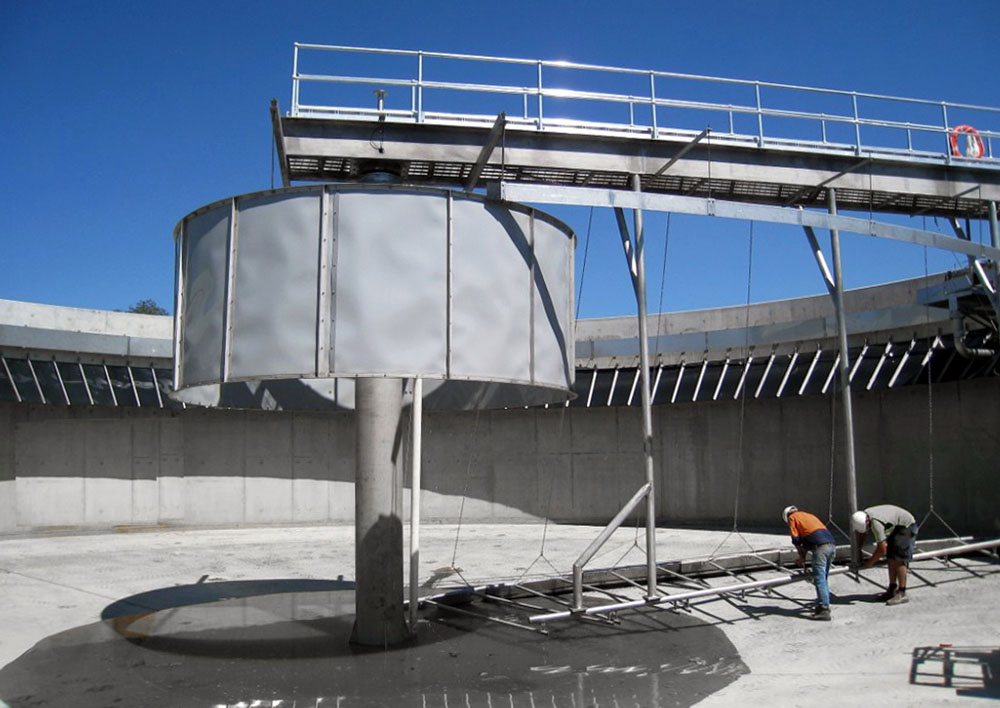

Scum Removal: A radial surface scum scraper with a hinged skimmer blade and self-flushing scum box efficiently collects and removes surface scum. A mechanically activated reflux valve ensures smooth scum discharge, while a rubber wiper continuously cleans the scum baffle.

LaunderShield®: A fibreglass or stainless steel interlocking cover system that blocks 100% of sunlight, preventing algae growth and reducing maintenance while maintaining clarifier performance.

EdiGate®: A flocculation feedwell system that eliminates mechanical mixing by reducing jetting and improving sludge settling. Available in fixed and hinged gate designs, with double-gate options for enhanced flow dissipation in larger installations.

Why choose to work with Hydroflux Industrial?

Hydroflux’s team includes qualified civil, mechanical, chemical, and electrical engineers, as well as experienced project managers, site supervisors, commissioning engineers, and service technicians. With offices located across Australia, Hydroflux ensures a strong local presence throughout the duration of every project. All projects are carried out under externally certified occupational health and safety and environmental management systems.

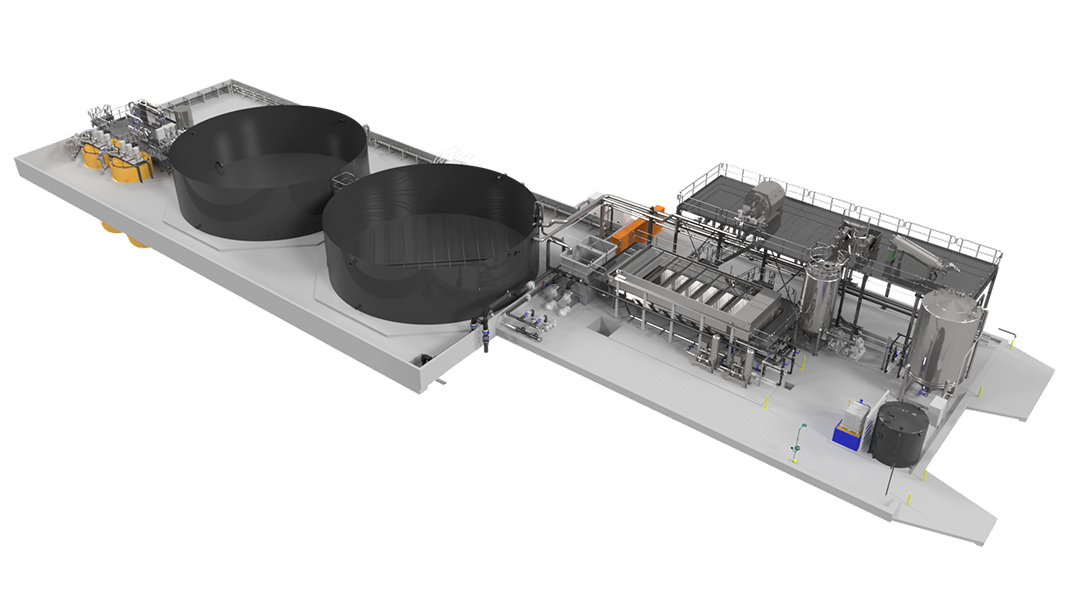

Hydroflux designs and constructs comprehensive wastewater treatment systems that incorporate various types of processing equipment, including screens, physical/chemical, biological, and tertiary treatment technologies to enable high-quality discharge or water reuse.

Below is a 3D drawing of a treatment plant constructed by Hydroflux that incorporated balancing, heat recovery, rotary screening, DAF, and sludge dewatering.

Contact us for a technical discussion about how we can assist you with your wastewater treatment facility.

Sustainable Solutions

As Australia’s first certified carbon-neutral water and wastewater chemical supply and service business, we focus on sustainability. Developing and delivering sustainable solutions for treatment plant operation and maintenance is at the core of what we do. Our equipment is the most sustainable in the Australian and New Zealand markets and is also carbon-neutral. Click here to find out what this means for you.