Belt Press

Belt Press – Continuous Sludge Dewatering for Large Volumes

Hydroflux can provide a range of belt presses with up to 3 m belt width, which allows for the treatment of very large flows.

The belt presses are designed with thickening trommels or gravity drainage decks to further increase the capacity for lightly loaded slurries ranging in size from 0.5 m to 3 m belt width.

- Very high capacities

- Continuous process

- Proven technology

- Low capital cost

- Suitable for many different types of primary and biological sludges

Capacities and Models

The Hydroflux belt press is available with belt widths ranging from 500mm to 3000mm. The capacity of a belt press is based on a combination of hydraulic and solids loads. Please contact Hydroflux for more information.

| Model Number | Max Hydraulic flow (m³/h)* | Max solids load (kg/h) |

|---|---|---|

| HY-PRESS® 500 | 1-4 | 80-100 |

| HY-PRESS® 1000 | 4-8 | 160-200 |

| HY-PRESS® 1500 | 6-12 | 240-300 |

| HY-PRESS® 2000 | 8-16 | 320-400 |

| HY-PRESS® 2500 | 16-25 | 400-500 |

*typical capacities, consult Hydroflux Industrial for specific data.

Why choose to work with Hydroflux Industrial?

Hydroflux’s team includes qualified civil, mechanical, chemical, and electrical engineers, as well as experienced project managers, site supervisors, commissioning engineers, and service technicians. All projects are carried out under externally certified occupational health and safety and environmental management systems.

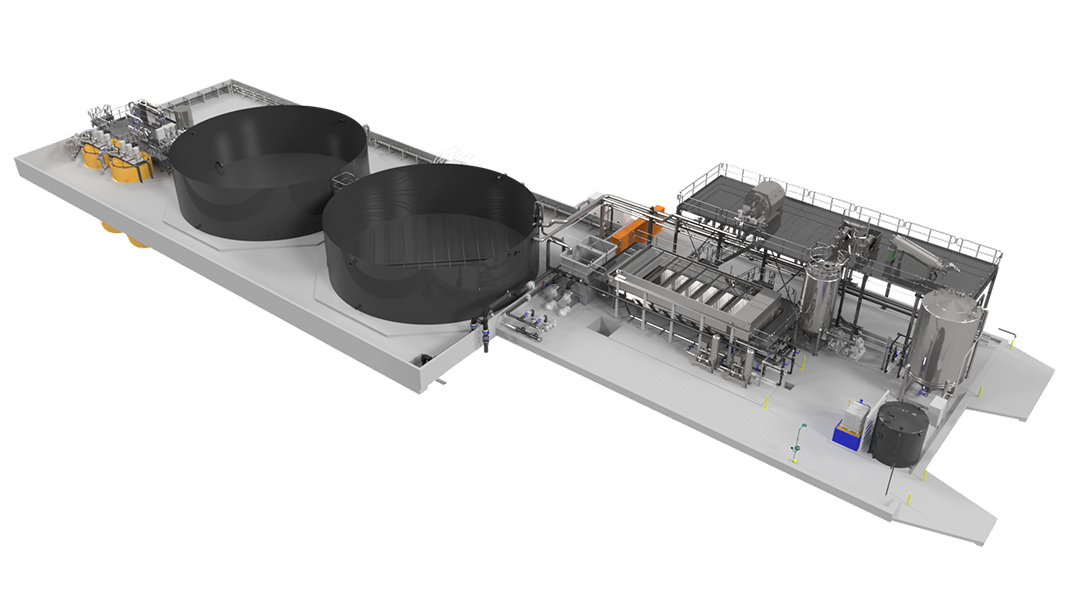

Hydroflux designs and constructs comprehensive wastewater treatment systems that incorporate various types of processing equipment, including screens, physical/chemical, biological, and tertiary treatment technologies to enable high quality discharge or water reuse. Below is a 3D drawing of a treatment plant constructed by Hydroflux that incorporated balancing, heat recovery, rotary screening, DAF, and sludge dewatering. Contact us for a technical discussion about how we can assist you with your wastewater treatment facility.

Sustainable Solutions

As Australia’s first certified carbon-neutral water and wastewater chemical supply and service business, we focus on sustainability. Developing and delivering sustainable solutions for treatment plant operation and maintenance is at the core of what we do. Our equipment is the most sustainable in the Australian and New Zealand markets and is also carbon-neutral. Click here to find out what this means for you.