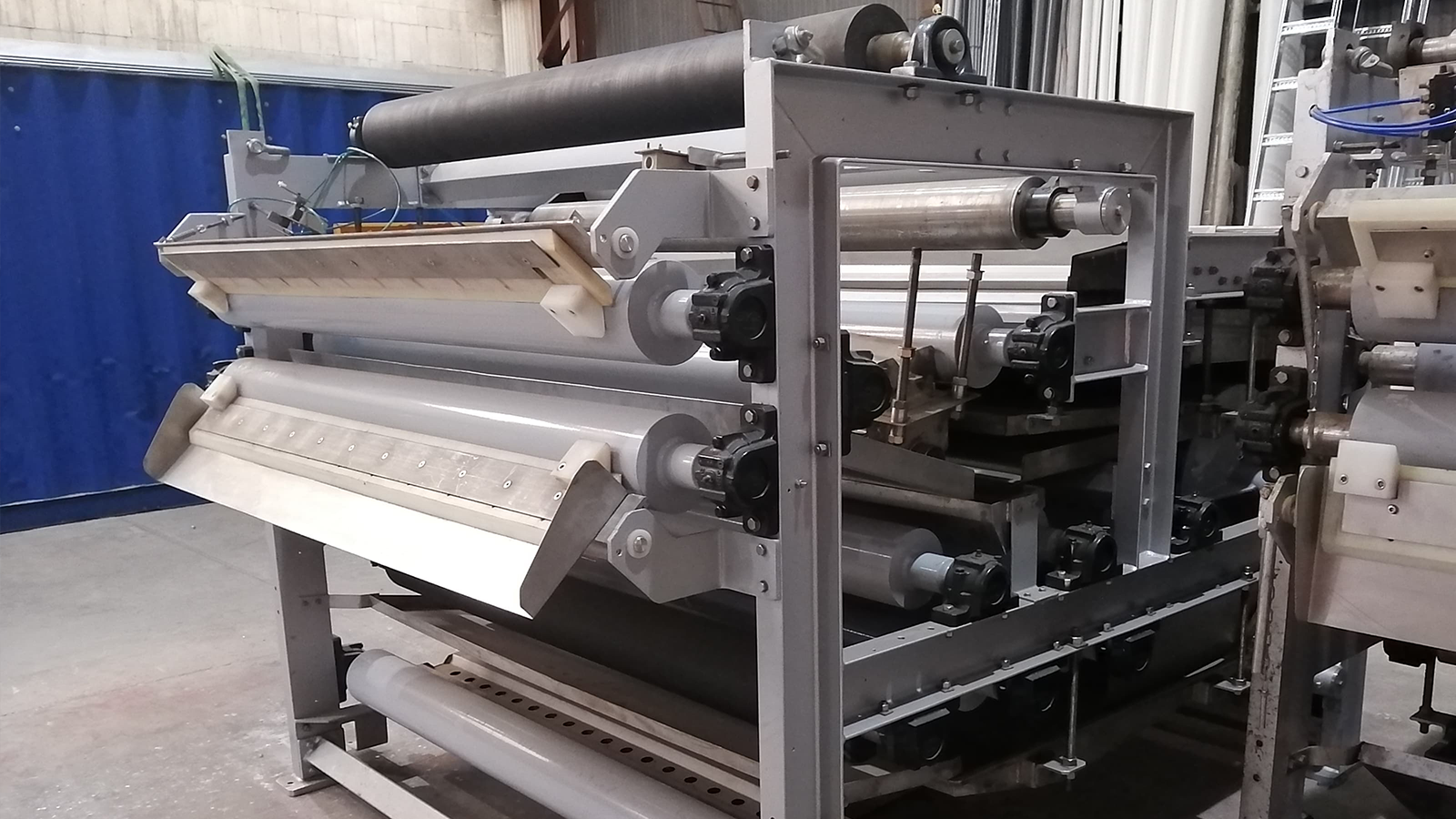

Belt Press

Hydroflux is proud to be Australia’s first water treatment and technology company to achieve Climate Active carbon neutral certification for our entire organization. As part of our climate change mission, we continue to research, develop and invest in sustainable technologies.

Now our journey continues – our main range of water technology and associated chemical products are Climate Active certified as carbon neutral. To read more on our journey, click HERE

Hydroflux can provide a range of belt presses with up to 3 m belt width which allows for treatment of very large flows.

The belt presses are designed with thickening trommels or gravity drainage decks to further increase the capacity for lightly loaded slurries ranging in size from 0.5 m to 3 m belt width

- Very high capacities

- Proven process

- Low capital cost

- Suitable for many different type of primary and biological sludges

Capacities and models

The Hydroflux belt press is available with belt widths ranging from 500mm to 3000mm. The capacity of a belt press is based on a combination of hydraulic and solids loads. Please contact Hydroflux for more information

| Model Number | Max Hydraulic flow (m³/h)* | Max solids load (kg/h) |

| HY-PRESS 500 | 1-4 | 80-100 |

| HY-PRESS 1000 | 4-8 | 160-200 |

| HY-PRESS 1500 | 6-12 | 240-300 |

| HY-PRESS 2000 | 8-16 | 320-400 |

| HY-PRESS 2500 | 16-25 | 400-500 |

*typical capacities, consult Hydroflux Industrial for specific data