Rotary Below Ground

In industrial applications, screening is essential as the first stage of treatment to remove bulk solids that would otherwise increase the solids and organic load on downstream plant.

Hydroflux Industrial can supply many different forms of screenings systems using various types of media and aperture size with each screen being selected based on the application, the solids load, type of solids and the hydraulic profile.

The development, selection and supply of screens is maintained in-house utilising one of a range of products from Hydroflux HUBER or Hydroflux Technology. In industrial applications, in-channel screens are often a cost effective option if the hydraulic profile permits, otherwise above ground rotary type screens are the alternative solution. Hydroflux Industrial can also offer screenings compaction and dewatering systems to reduce the volume of waste to be disposed of.

Hydroflux product solutions are fully equipped, ready for operation. This complete offer allows clients to consider the best technical solutions available via the most efficient process.

Find out more

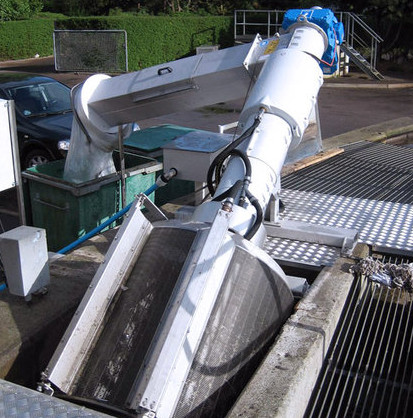

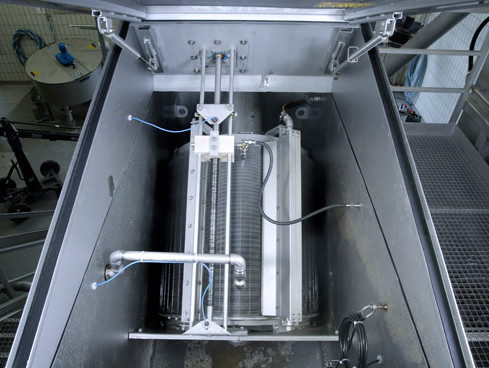

The wastewater flows into the open end of the inclined screen basket and then through the screen. Floating and suspended materials are retained by the bars of the screen basket.

Blinding of the screen surface generates an additional filtering effect so that solids can be retained that are smaller than the bar spacing.

At a certain difference in the water levels up and downstream of the screen, which is caused by screen surface blinding, the rake arm situated on the axle centre starts to rotate. Its tines, extending completely through the screen bars, cleans the basket, removes all the screenings, and conveys them into the centrally positioned trough with integrated screw conveyor.

As the screenings are conveyed and compressed within the inclined pipe, they are dewatered and compacted without any odour prior to being discharged into the customers container or a subsequent conveying unit.

Hydroflux Industrial supply a comprehensive range of below ground screens to suit virtually any industrial wastewater application

| Model Number | Treatable flow range (m3/h)* | Screen Diameter (mm) |

| Ro9/300 | 2-10 | 300 |

| Ro9/400 | 5-20 | 400 |

| Ro9/500 | 10-30 | 500 |

| RPPS/600 | 30-50 | 600 |

| RPPS/780 | 50-80 | 780 |

| RPPS/1000 | 80-130 | 1000 |

| RPPS/1200 | 130-175 | 1200 |

| RPPS/1400 | 175-255 | 1400 |

| RPPS/1600 | 255-350 | 1600 |

*typical capacities for industrial wastewater. Consult Hydroflux Industrial for detailed sizing

There are numerous advantages to the Ro9 and RPPS range of above/below ground screens:

- Screening prior to pumping, increasing life of pumps and reducing solids accumulation in pump wells.

- Screening prior to balance tank with no need for costly elevated screen platforms.

- Suitable for channel depths of up to 5 metres.

- Automatic operation via level control.

- Low headloss to avoid upstream issues in manholes and sumps.

- Integrated conveying and compaction of screenings.

There are numerous applications for Screens:

- Meat and poultry industry

- Dairies

- Beverage sector

- Fruit and vegetable processing

- Potato and potato chips

- Vegetable oil processing

- General Food industry

- Manufacturing, metal processing

- Industrial laundries

- Paper, cardboard and printing

- Potable water treatment

DESIGN CONSTRUCTION OPERATION

Engaging a professional wastewater treatment company to look after the entire wastewater project is a convenient, economical and hassle free option for industry.

Hydroflux Industrial can provide all process design works, manufacture and fabrication, construction and even complete operation of your wastewater treatment plant.

When Hydroflux Industrial provides complete solutions, we can either undertake a contract on a turnkey basis or work together with building services engineers and other construction professionals to ensure that the project is delivered smoothly, without interruption and on time.

BUILD OPERATE TRANSFER (BOT) FINANCING

The Hydroflux Group is able to offer a Build Operate & Transfer (BOT) option for water and wastewater assets in Australia and New Zealand. This innovative partnership arrangement strengthens existing strong bonds between Hydroflux and their customers for the long term.

Hydroflux, represented by a special purpose vehicle dedicated to the project, supplies the design, construction, financing, and operation of the water or wastewater plant. The plant is transferred to the client at the end of the contract, which is generally around 10 years.

Hydroflux also purchase existing water and wastewater plants on a similar basis, which releases cash to our clients for either returning or distributing to investors or for funding other investments in their core business.

The multidisciplinary structure of the Hydroflux group including design, construction, equipment supply and operation makes Hydroflux the ideal BOT water and wastewater partner.

Please contact Hydroflux if would like to explore the option of either acquiring a new water or wastewater facility without capital outlay or would like to free up cash by selling your existing water or wastewater assets.