Chemical Handling and Dosing

Hydroflux is proud to be Australia’s first water treatment and technology company to achieve Climate Active carbon neutral certification for our entire organization. As part of our climate change mission, we continue to research, develop and invest in sustainable technologies.

Now our journey continues – our main range of water technology and associated chemical products are Climate Active certified as carbon neutral. To read more on our journey, click HERE

The use of the correct chemicals and chemical doing equipment is essential to the effective operation of your water or wastewater treatment plant. Hydroflux Industrial has the expertise to:

- Determine the most appropriate chemical process for each and every application

- Select the most suitable dosing equipment

- Design and build high quality robust polymer blending and dosing systems

- Design the complete chemical dosing plant in accordance with the appropriate regulations

- Conduct all installation and commissioning works

Safe chemical separation and a secondary containment system is required under the Health and Safety at Work (Hazardous Substances) Regulations, and is enforced by WorkSafe NZ and the EPA. It is therefore essential that when you are considering installing a wastewater treatment plant that utilises chemicals which are considered dangerous goods, you engage a company that has experience and a full understanding of the legislation.

There are no compromises in dangerous goods storage. Inexpensive chemical storage and dosing equipment that does not comply can have serious implications for your employees, the environment and your business.

Hydroflux Industrial design safe and compliant chemical storage facilities to suit virtually any chemical and delivery method.

If you are looking to purchase chemicals, please visit Hydroflux Utilities.

Find out more

Many water wastewater treatment plants rely on the use and dosing of chemicals for effective operation. Whether chemicals are being used for pH control, coagulation, flocculation, CIP, descaling, emulsion breaking, oxidation, disinfection or many other reactions, a reliable and safe means of storage and dosing of chemicals is of upmost importance.

Enclosed chemical dosing pump cabinets

Hydroflux has vast experience in the design and construction of chemical storage and dosing facilities including:

- Bulk chemical storage with a range of IBC bunds, dosing systems and level control options

- Various types of doing pumps and control systems

- Automated pH probe washing

- Automated polymer blending and dosing equipment for emulsion or powdered polymers

- Integrated back to base alarms

IBC Bunding

Hydroflux Industrial has developed and utilises several types of bund designs to store IBC’s in accordance with regulatory requirements. The photo below shows some of most popular IBC bunds. Please refer to photo gallery tab for other designs.

IBC bunds for temporary storage

Of all the chemicals used on a water or wastewater treatment plant, the polymer can be one of the more difficult to manage properly. Polymers are usually supplied as a product that needs further “manufacturing” before use.

HydraBLEND® is a range of polymer blending and dosing systems designed and manufactured by Hydroflux Industrial for effectively blending and dosing polymer for use in the treatment of water or wastewater, or for flocculation of sludge.

Twin polymer system selected for clarification and sludge flocculation at a wastewater treatment plant

The systems are designed for emulsion or powdered polymers in a range of capacities from 1 lire or Kg per hour upwards to suit any application. The HydraBLEND® system is designed to efficiently wet or invert the polymer before hydration to enable uncoiling to occur thus maximising the efficiency and reducing consumption.

The systems can be provided with single or multiple dosing pumps to enable the polymer to be pumped to multiple places such as DAF systems and dewatering plant.

HydraBLEND® is a range of polymer blending and dosing systems designed and manufactured by Hydroflux Industrial.

A hybrid liquid and powdered HydraBLEND® polymer make up and dosing system

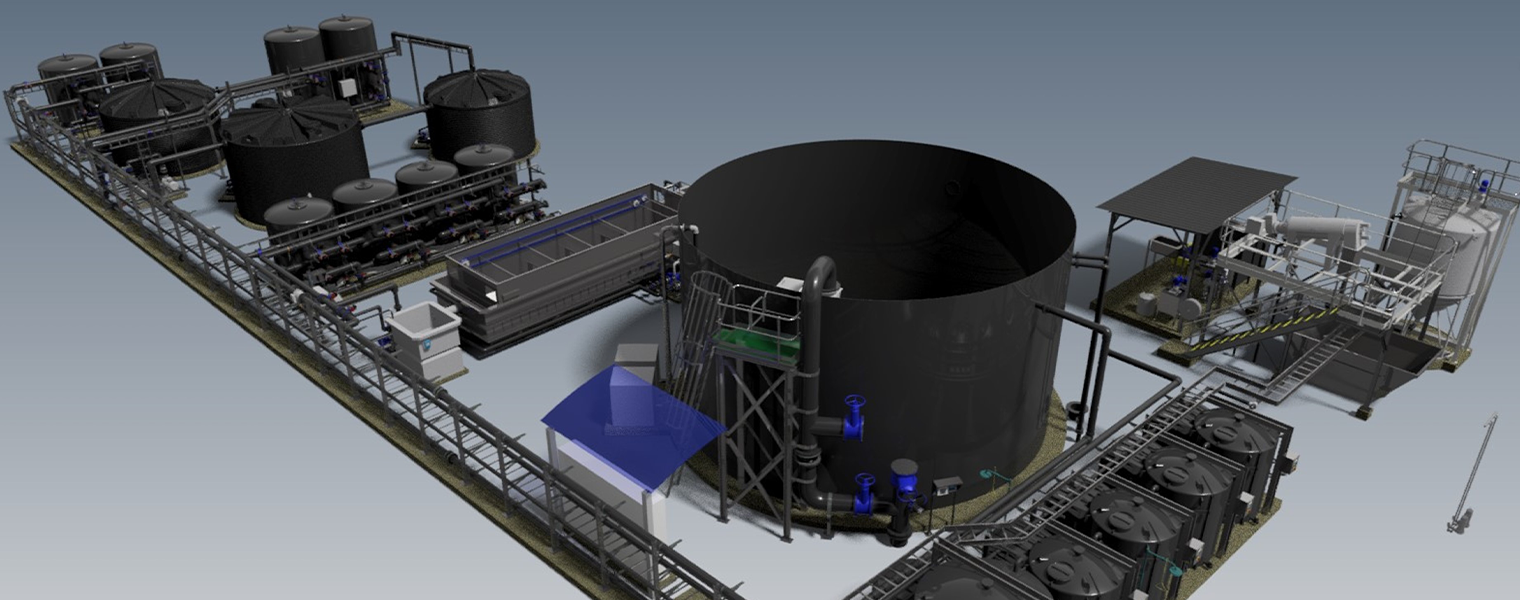

Chemical dosing systems are just one process component in complete water or wastewater treatment plant. Hydroflux has the skills and expertise to conduct any design and construct project incorporating a range of process equipment with appropriate chemical storage, dosing and conditioning. Hydroflux employs qualified civil, mechanical, chemical and electrical engineers plus a team of experienced project managers, site supervisors, commissioning engineers and service technicians based in offices throughout New Zealand providing a local presence throughout the duration of the project.

All projects are conducted under externally approved occupational health and safety, and environmental management systems.

Hydroflux design and construct complete wastewater treatment systems involving many different type of chemical dosing equipment.

Hydroflux is Australia’s first Water-tech company to achieve Climate Active certifications which means by engaging with Hydroflux you are supporting positive and verified action on climate change.

Construction of a turnkey wastewater treatment plant at a new food production facility in SA

The Utilities division provides the link to integrating the Hydroflux® businesses by providing a comprehensive support network for customers throughout New Zealand.

Hydroflux Utilities provides virtually any form of wastewater management programs including:

Chemical optimisation

Hydroflux has a comprehensive range of coagulants and flocculants suitable for conditioning wastewater or sludge. The most appropriate chemical program will be determined before commissioning based on experience, or test work if possible, and long-term cost-effective chemical supply contracts can be arranged.

Preventative maintenance and service

Our engineers and technicians will discuss service and maintenance programs with you during construction of the wastewater treatment plant so that you can be assured that the system will perform consistently from day 1. There are many types of programs available from routine preventative maintenance, periodic service and overhauls, to complete plant operation. Our technicians are available 24/7 to attend to unforeseen breakdowns.