Solid Waste Digestion

AAT & Hydroflux provide solutions, no matter from what source material you generate biogas.

AAT plants have been in operation internationally over many years for sludge digestion on large scale farms, disposal companies and in the food industry. AAT is a competent partner for complete treatment systems, plant equipment including single modular units like waste pre-treatment and pasteurization.

Do you have an organic source material suitable to create biogas?

The conversion of organic material into biogas is a convincing concept both from an economic and ecological perspective.

Instead of disposing of materials at high costs or using other less lucrative recycling options, the material and energy is wholly utilized and fully converted into marketable products whilst reducing CO2 and Methane emissions.

AAT has designed and realized biogas facilities for over 150 different substrates. The gained biogas can be converted into electricity and long-distance heating or prepared as bio-methane. Digestate remains can be converted into valuable fertilizer.

Find out more

There are a multitude of potential sources of feedstock for anaerobic digestion, such as:

- Distilleries

- Breweries

- Dairy processors

- Food processors

- Pre-sorted municipal waste

- Water treatments plants

- Farm manure

Sludge from primary water treatment, expired food and organic food waste, animal manure, spent grain from brewing or distilling are some examples.

Food remains, biowaste and kitchen waste provide ideal organic recycling material.

Different substrates require different digester technology.

| Digester Type | Common use |

| Flat (Low profile) digester | 1st stage digesters for buffering and hydrolysing AD of agricultural waste & plants AD with integrated gas storage |

| Hydraulic Digestor (without mechanical mixer) | Sewage plants, food waste, sludges from industrial water treatment and other high solids applications |

| CSTR Digestor with central agitator | Sewage plants, food waste, sludges from industrial water treatment and other high solids applications |

| MSB Digestor | Whey plants and wastewater with high fractions of suspended matter and also high fat contents |

| UASB Digestor | High strength wastewater with low solids content in applications such as breweries, beverage, dairy and paper |

Please scroll down for more information on the different types of digesters.

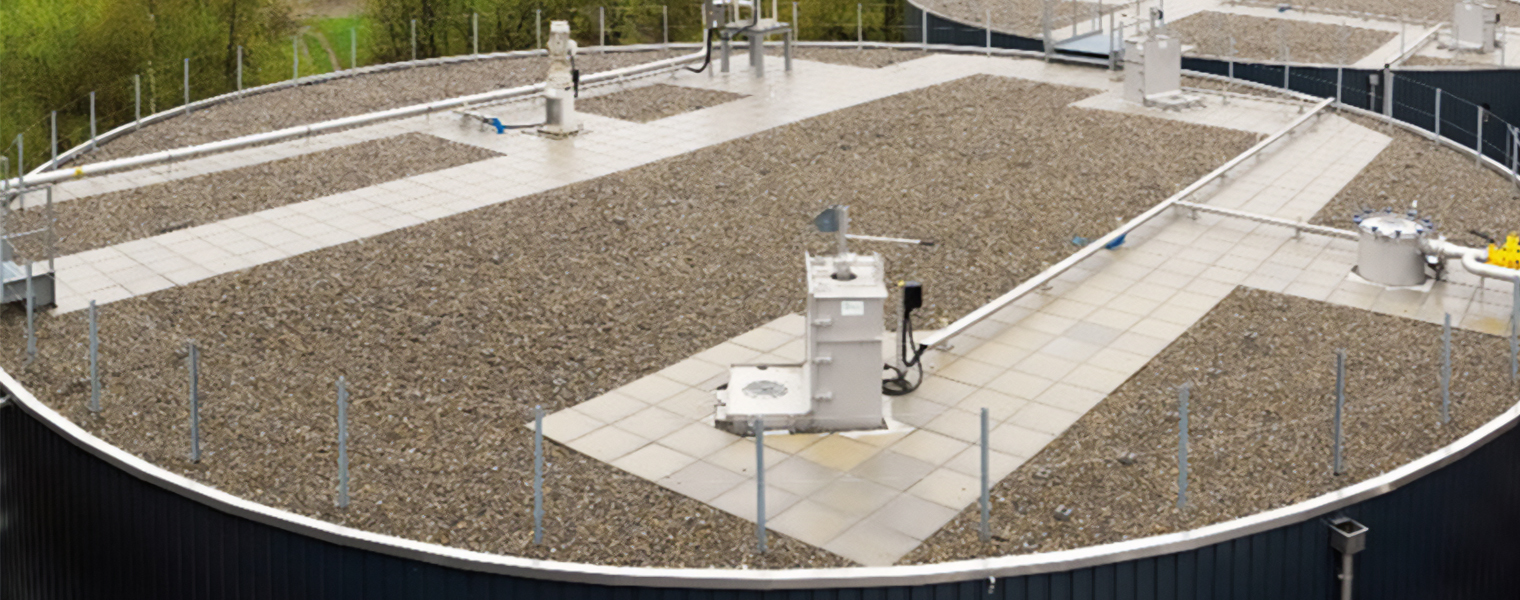

Flat (low profile) digester

Some of the key features include:

- Digester dimensions: low height / diameter ratio

- Construction: steel reinforces concrete floor, walls and ceilings with center column

- Agitation: vertical shaft mixer combined with submersible mixer

- Feeding system: dry material feeder

- Heating: heating coils inside digester

- Desulphurization: integrated in digester or external biological desulphurization

Bolted low profile digester with gasholder

Some of the key features include:

- Construction: steel reinforces concrete floor, bolted steel walls and center column

- Agitation via mixer with externally mounted drive

- Optional insulation and heating coils inside digester

- Optional desulphurization integrated in digester or external biological desulphurization

- Double membrane gasholder

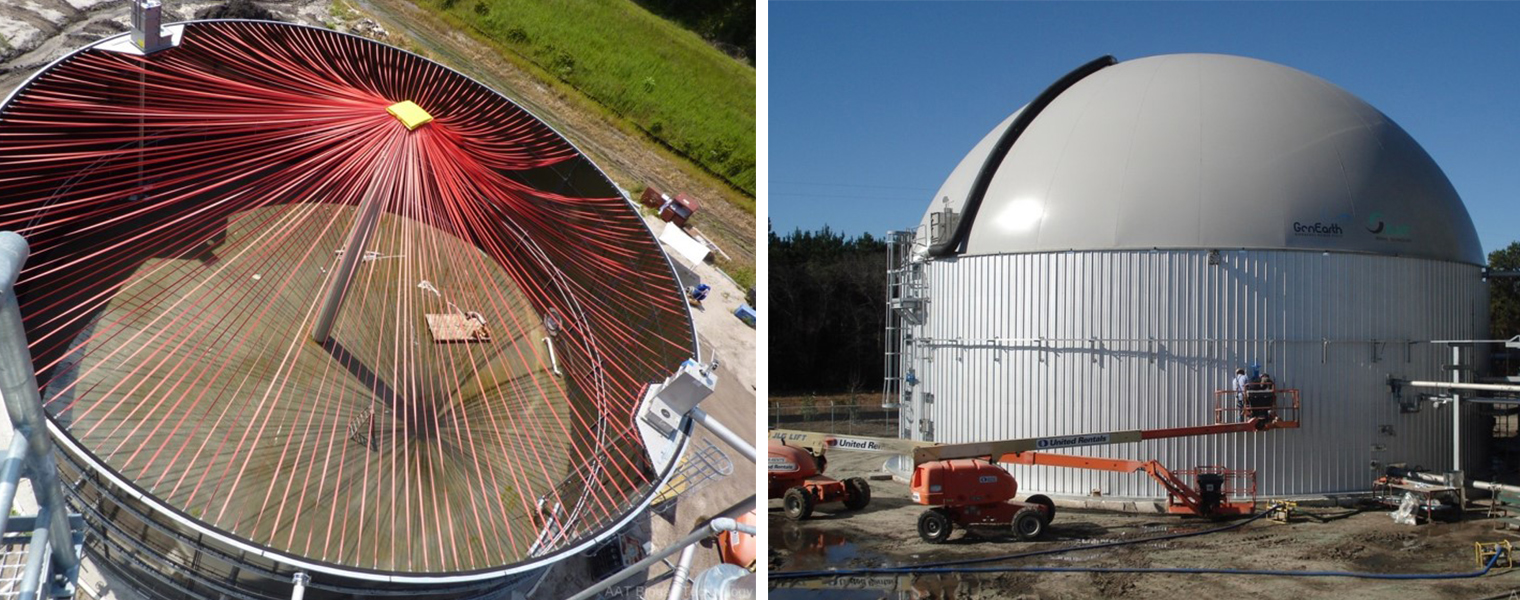

Hydraulic digester

The AAT hydraulic digester produces more gas for almost zero operating cost.

Hydraulic Digesters for substrate with a high sediment content

Some of the key advantages include:

- Simple and robust construction

- High treatment efficiency

- Very low operation and maintenance costs

- Sludge withdrawal at ground level

- No moving parts or mixers required inside the digester

- Higher gas production than with CSTR digesters through plug flow principle

- Mixing also during a power blackout

- Up to 12% Dry Solids Content

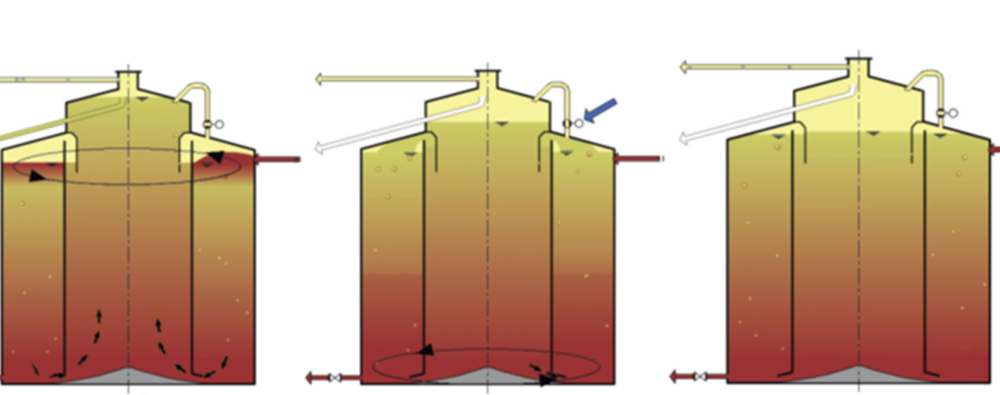

Picture 1 – Maximum level difference between main digestion chamber and final treatment chamber (gas discharge from outer chamber is closed)

Picture 2 – Hydraulic mixing process (gas discharge from outer chamber is open)

Picture 3 – State after completion of hydraulic mixing process (gas discharge from outer chamber is closed again)

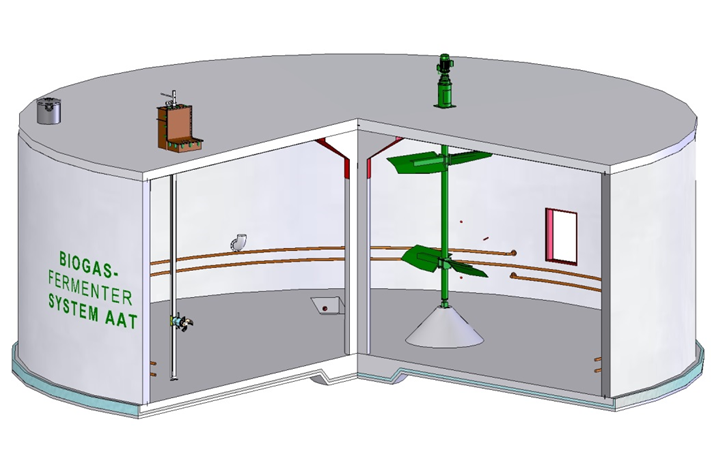

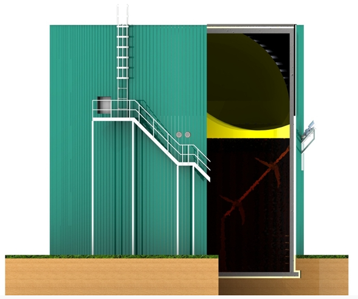

CSTR Digester

Some of the key advantages of the CSTR Digester include:

- Completely mixed reactor with vertical agitator for substrates with high solids content

- Manufactured from prefabricated steel plates or pre-stressed concrete with PE protection layer

- Epoxy or glass enamel coated tank shell with stainless steel roof, long term resistant to corrosion

- Sizes from 250m3 to 9000m3

MSB Digester

Some of the key features of the MSB Digester include:

- The patented Mixed Sludge Bed Digester has been developed for wastewater, highly polluted with organic matter

- It is especially suited for wastewater with a high fraction of suspended matter and also with high FOGs content

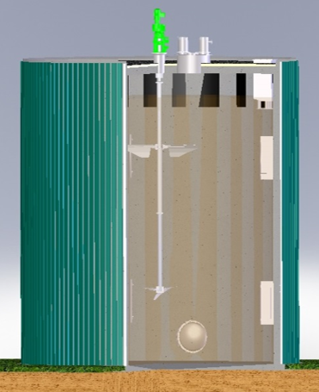

Compact Digester

The AAT compact digester plant combines sludge digestion and gas storage into a simple integrated system. The inclined agitator is used for gentle agitation of the primary sludge and guarantees effective mixing and de-gassing of the substrate. The mixing intensity is adjustable via VSD to suit the operating conditions and reduce energy consumption.

Utilizing the space above the digester for gas storage provides protection for the gas membrane, saves costs and reduces the footprint of the plant.

Some of the key advantages of the Compact Digester include:

- Easy operation and maintenance of the agitator (no access into the digester or opening of the gas hood required)

- Optimal mixing of the fresh substrate into the active biomass

- Prevention of generation of sediment layer and floating matter

- Continuous removal of nondegradeable matters via the sediment discharge

- Low investment cost and operating cost

- Long equipment life through gentle operation

- Reduced footprint with ability to act as a low gas pressure storage

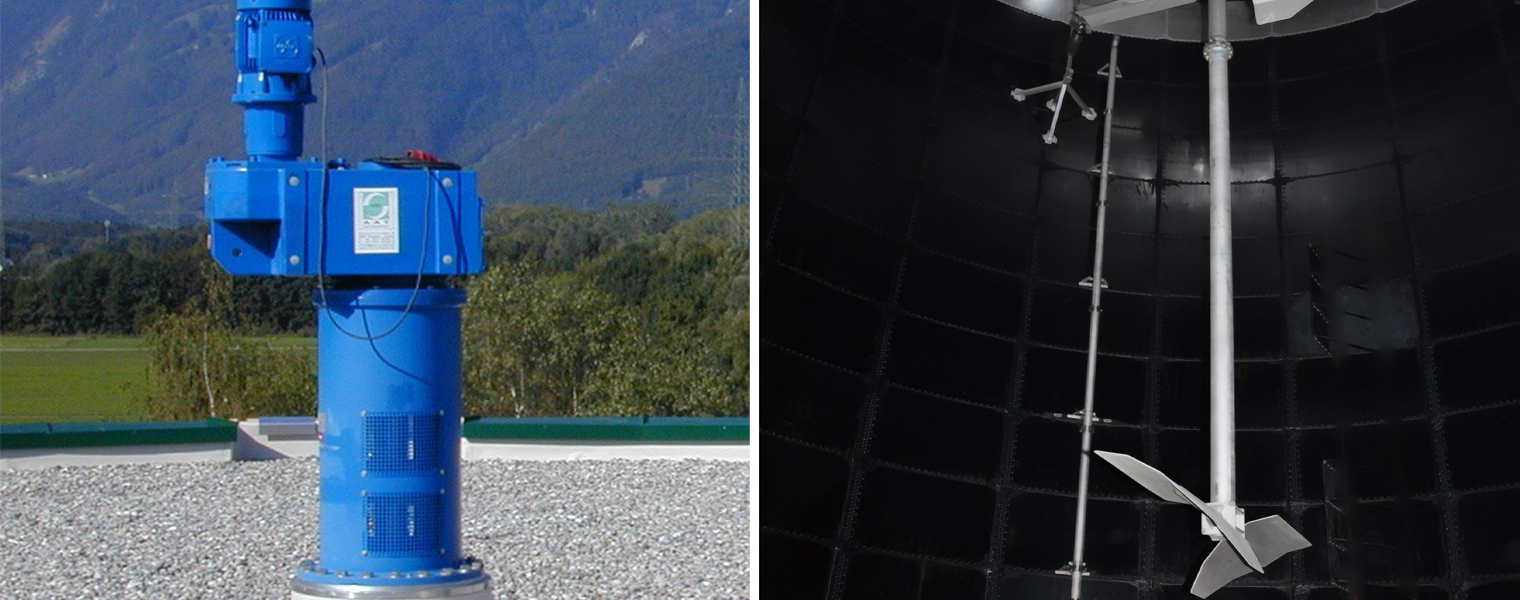

Vertical agitator, suspended

The suspended agitator is used to the sludge in the digester and admix and fresh sludge into a homogeneous substrate mixture permitting a stabile fermenting process. The agitator produces an axial flow from top to bottom which ensures quick and efficient mixing of floating matter as well as an admixture of sludge at the bottom.

The design of the agitator is adapted to suit the characteristics of the substrate and digester dimensions.

Some of the key advantages include:

- High efficiency digester mixing

- Optimized mixing with minimum of energy, also for higher viscosities

- Flow optimized agitator blades

- Robust and low maintenance system

- All maintenance relevant components are located outside if the digester tank to enabling easy servicing without emptying the digester.

Vertical agitator, top and bottom mounted

The is top and bottom mounted agitator is used to the sludge in the digester and admix and fresh sludge into a homogeneous substrate mixture permitting a stabile fermenting process. The agitator consists of 2x optimized impellers in the bottom and ceiling area of the tank.

The design of the agitator is adapted to suit the characteristics of the substrate and digester dimensions.

Some of the key advantages include:

- High efficiency digester mixing

- Flow optimized agitator blades

- Robust and low maintenance system

- All maintenance relevant components are located outside if the digester tank to enabling easy servicing without emptying the digester.

- Floor storage with maintenance free, special ceramics bearings

Vertical agitator, with floating blade

The is top and bottom mounted agitator uses a floating blade to automatically height adjust to the level on the tank. It has been designed especially for use in hydrolysis tanks, buffer tanks with variable levels or for direct mixing of digesters. The agitator reliably prevents the development of surface crusts and mixes the sludge in the digester and admix of fresh sludge into a homogeneous substrate mixture permitting a stabile fermenting process.

The agitator consists of 2x optimized impellers in the bottom and ceiling area of the tank.

Some of the key advantages include:

- Highest efficiency digester mixing for tanks with variable levels

- Self adjusting “floating” blade for homogenous mixing and prevention of surface crusts

- Flow optimized agitator blades

- Robust and low maintenance system

- All maintenance relevant components are located outside if the digester tank to enabling easy servicing without emptying the digester.

- Floor storage with maintenance free, special ceramics bearings

Rohkraft Ing. Karl Pfiel GmbH – Reidling / Austria

Substrate: Pig manure, energy crops

Thermal use: Heat supply of the village Reidling

Startup: 2003

Capacity: 43,7 t/d (15.950 t/a)

Gas yield: 11.000 m3/d

Produced elec. energy: 22.750 kWh/d

Produced therm. energy: 26.250 kWh/d

Recycling Energie AG – Nesselnbach / Switzerland

Substrates: Slaughterhouse waste, bio waste, pig manure, whey, vegetable waste.

Thermal use: Gnadenthal retirement home, personal use, hygienisation and heating.

Startup: 2011

Capacity: 150 t/d (54.750 t/a)

Gas yield: 26.400 m³/d

Prod. elec. energy: 2x 1,1 MW, Prod. therm. energy: 2x 1,2 MW

CS-Bioenergia – Curitiba / Brazil

Substrate: 330.000 t/a sewage sludge, 44.000 t/a food waste, 11.000 t/a fruit- and vegetable waste

Thermal use: Sludge drying process

Startup: 2017

Capacity: 900 t/d sewage sludge, 120 t/d food waste, 30 t/d fruit- and vegetable waste

Gas yield: 23.000 m³/d

Prod. elec. energy: 2,4 MW, Prod. therm. energy: 2,5 MW

Jakob Bösch AG – Aedelswil / Switzerland

Substrate: Food and market leftovers, spoiled food, slaughterhouse waste, pig manure

Startup: 2005

Capacity: 110 t/d

Gas yield: 9,000 m³/d

Prod. elec. energy: 24,100 kWh/d

Prod. therm. energy: 27,100 kWh/d

Kapitanivska Ptakhofabryka“, – Novomirgorodskii, Ukraine

Substrate: Sugar beet chips

Hydraulic digester: 4 x 5.000 m³

Gas storage: 2 x 3.400 m³

Gas yield: 62.000 m³/d

Installed electric power : 6,0 MW