Multimedia Filtration

The HyPURE Multimedia filtration system is a compact, robust and economical solution designed and manufactured by Hydroflux. With nearly 50 systems in operation or under construction since inception, the HyPURE multimedia filtration is setting a new standard for filtration systems.

Pressurised media filtration provides a simple solution to treating raw water and wastewater to remove fine particulates, colloidal solids as well dissolved organics and heavy metals.

With some modifications to the process, the MMF systems can be design to accommodate Greensand to enhance metal removal or activated carbon for numerous other applications.

The HyPURE range of MMF can be utilised in a wide variety of applications including:

- Pretreatment of advanced water from industrial wastewater sources.

- Production of process and potable water for industry from bore water and surface water supplies.

- Pretreatment prior to demineralisation or ion exchange.

- Pretreatment prior to HyPURE RO for hygienic process water or production of infant formula, dairy products, beverages, cosmetic and pharmaceutical products.

- Treatment of wastewater to meet strict environmental discharge standard – particularly with the inclusion of green sand media.

- As a component in Zero liquid discharge plants from industrial processes.

Our expertise in wastewater gives us a unique edge in the industry, as we design our systems to manage water sources with the highest risk of scaling and biofouling. This conservative approach leads to extended filter life, low energy consumption, minimum downtime and maximum recovery.

Find out more

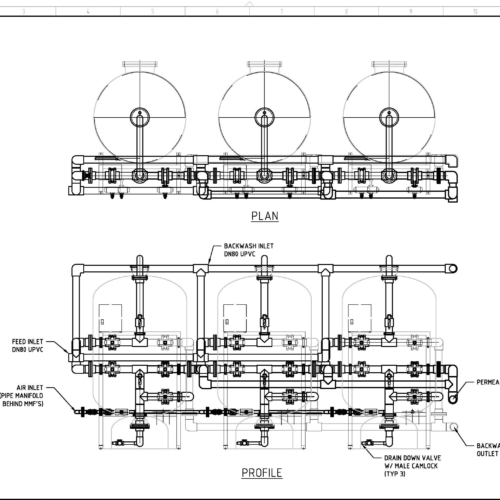

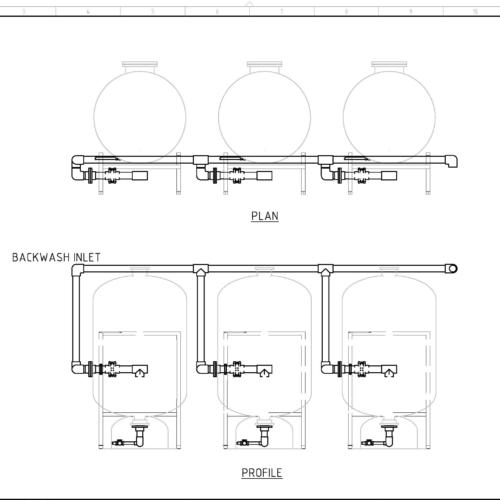

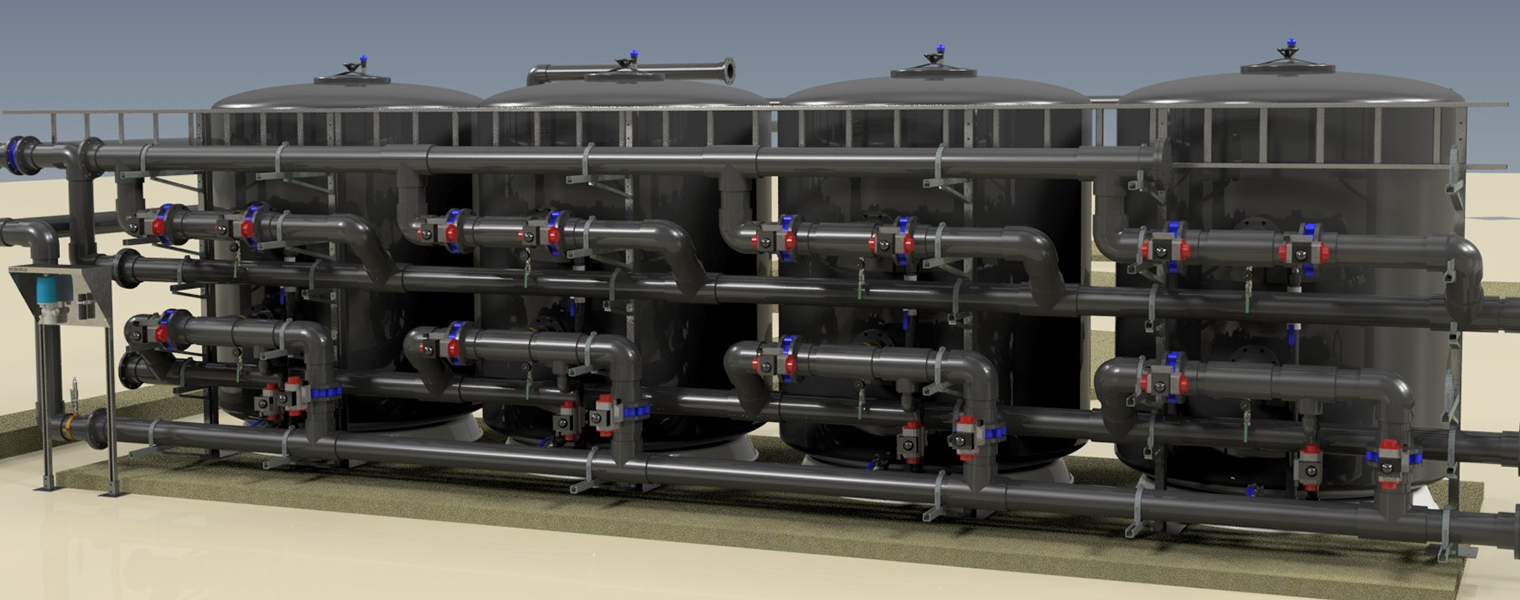

Pressurised Media filtration involves the use of a pressure vessel, filled with media specifically selected for the treatment application. Hydroflux offer a wide range of vessel designs and materials including stainless steel and painted mild steel with the most commonly utilised material being fiber reinforced plastic (FRP).

Unlike most filtration system suppliers, Hydroflux manufactures and assembles its own FRP vessels.

The filtration process

The first step of the filtration process involves raw or waste after entering the pressure vessels through a set of top mounted diffusers. The diffusers disperse water inside the vessel, ensuring a uniform downflow velocity through the vessel.

Once the water is dispersed within the vessel, it flows down through the media bed. Hydroflux custom designed vessels allows flexibility in bed depth without reducing free-board above the vessel, which is key to effective backwashing. The typical bed depth is 800mm – 1200mm, but deeper beds can also be provided for special activated carbon adsorbtion and desalination calcite remineralisation processes.

As water flows through the bed pollutants are removed through several physio-chemical processes, including size exclusion (filtration), adsorption and cake formation within the bed. Biological degradation of pollutants can also occur in some filters, although in many cases this is not desired due to the sloughing of bacterial colonies into the treated water and reduced filter run-times. Hydroflux understand the challenges of biofouling within filtration beds and offer simple solutions for maintaining the integrity of the filtration media.

The filtered water is collected by a bottom nozzle plate, which prevents media from escaping in the treated water. The filtered product is typically directed to a filtration tank which provides a reservoir for the backwash process.

In-house designed and manufactured pressure filtration vessels and processes

Backwashing

Hydroflux HyPURE systems used advanced automation for the control of the backwash cycle to minimise unnecessary backwashing during periods where the solids loading in the feed water is low. This is particularly advantageous in biological wastewater recycling, where changes in upstream conditions can lead to volatility in the solids and organic content entering the filters.

For most HyPURE applications, Hydroflux will also provide an air scour as part of the backwash cycle. Dedicated air scour blowers are provided to enhance bed cleaning and prevent rat-hole formation.

For most HyPURE applications, Hydroflux will also provide an air scour as part of the backwash cycle

MMF systems can be designed to target specific pollutants in the wastewater via the use of one of a range of specialised media.

Dissolved metals for example can be removed by using a specialist media such as Greensand. By catalysation, Green Sand promotes the formation of metal oxides and metal hydroxides within the filtration bed itself.

Many different types of media targeting the removal of specific contaminants can be used in Hydroflux MMF systems

Activated Carbon

Activated carbon can also be used as a media in Hydroflux MMF vessels. Activated Carbon filters are usually installed after multimedia filtration and acts as an adsorbant to remove many compounds such as:

- Taste, odour and colour

- Organic materials

- Disinfection by-products

- PFAS and engorging contaminants

- Heavy metals

Hydroflux HyPURE MMF vessels can be used as activated carbon filters to remove organics or PFAS

What is the capacity range of the HyPURE Multimedia systems?

The HyPURE range is individually designed to suit customer requirements, the treatment capacity can range from <1m 3/D up to and above 5000 m3/D. Generally, flows above this are more suited to gravity filtration. We have standard sizes that we manufacture, but due to the variability of the site conditions, feed water quality and available space in the plant each solution must be tailored to suit.

What are the typical sizes of the pressure filtration vessels.

Pressure filtration vessels are generally cylinders, mounted horizontally or vertically. Vertical vessels range from 300 mm to 3 m in diameter. Horizontal vessels are generally 2.2 m in diameter to minimise shipping costs but can provide anywhere up to 10 m2 in available filtration area by increasing the vessel length.

Hydroflux MMF vessels range in size from 300 mm to 3 m in diameter.

What type of maintenance is required on a HyPURE Multimedia system?

HyPURE MMFs are designed for extended maintenance free operating periods. Typically, no maintenance is required for several years. The most frequent activity required is media replacement, which can be every 5 to 10 years for sand filtration down to 3 to 6 monthly for activated carbon filtration.

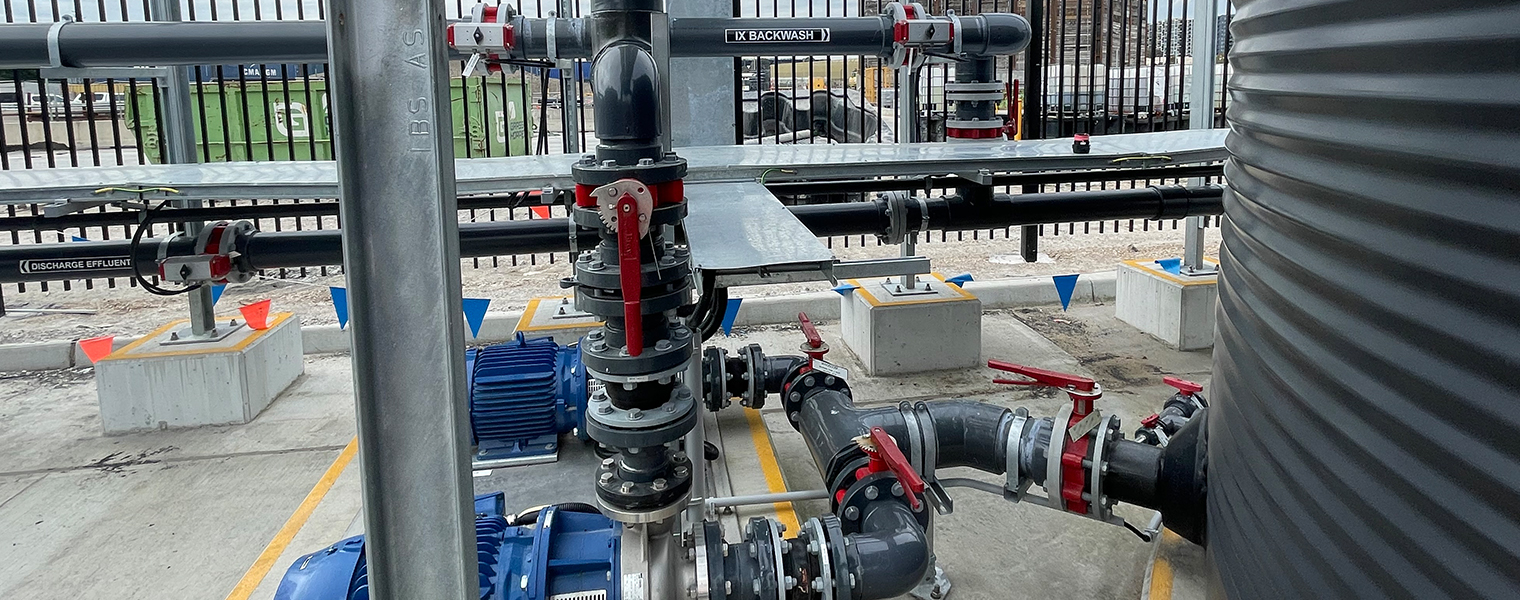

The HyPURE system has several advantages over conventional media filtration systems, as the use of bottom nozzle plates means that less downtime is needed for maintenance compared with bottom lateral diffuser designs. In addition, the HyPURE system uses independent control valves compared with a single multiport valve to control the filtration cycle.

Multiport valves are prone to breakdowns/failures and generally have a high replacement cost and long lead time. Individual parts for control valves and actuator heads are readily available and low cost to purchase. Operation of the HyPURE Multimedia plant can also be controlled remotely through the HyCONNECT® system.

HyPURE MMFs are designed for extended maintenance free operating periods

Do Multimedia Filtration system require a lot of power?

Generally speaking, MMF systems require a lot less power than other types of filtration technology, such as ultrafiltration and reverse osmosis. The power is also influenced greatly by the feed TSS. The rate which the media bed differential pressure increases subsequently increases power required by the feed pump. The media bed also requires more frequent backwashing which impacts on the total energy consumption of the plant. Generally MMF systems operate at between 0.8 and 1.5 BarG.

How small are the particles which can be removed by the HyPURE Multimedia filtration?

The purpose of the filtration bed is to capture fine colloidal material down to <2micron, which is 10x smaller than a human hair.

Do Multimedia Filtration system require a lot of power?

Generally speaking, MMF systems require a lot less power than other types of filtration technology, such as ultrafiltration and reverse osmosis. The power is also influenced greatly by the feed TSS. The rate which the media bed differential pressure increases subsequently increases power required by the feed pump. The media bed also requires more frequent backwashing which impacts on the total energy consumption of the plant. Generally, MMF systems operate at between 0.8 and 1.5 BarG.

MMF systems generally require a lot less power than other types of filtration technology

Can the HyPURE Multimedia filtration system handle iron, manganese and other heavy metals in the feed water?

MMF systems can handle dissolved heavy metals within the feed water, as long as the total concentration does not exceed the design feedwater levels of the filter. Hydroflux® offer a range of specialised media to maximise the metal precipitation and removal within the filter bed. This is done by catalysing the formation of metal oxides and metal hydroxides either in front of the MMF or within the filtration bed itself.

Hydroflux® offer a range of specialised media to maximise the metal precipitation

How is the media replaced?

Media replacement can be done by several different means. Spent media is usually sucked out of the vessel via a vacuum truck and carted from site to be recycled or disposed. It is also possible to unload some low-density media (such as activated carbon) via a hydraulic transfer to a specially designed screen to capture the media.

The most common method of loading the replacement media is directly filling from an elevated work platform or conveyor into the top of the vessel. Media can also be loaded in via large bulk bags or pumped in from trucks or small tanks with specially designed loading systems. Hydroflux® hold media loading systems in our warehouse to assist customers with media replacement.

What is the purpose of an air scour in the backwash cycle of an MMF?

Air scouring of the filter bed is recommended to extend the bed life. During operation and backwashing, the media bed can form “rat-holes” or channels which allow pollutants to pass through unhindered. Air scouring the bed provides a mechanisms for more aggressive cleaning. Air scouring allows the media bed to be completely and evenly mixed within the vessel. The subsequent backwashing and settling of the media allows the bed to reform evenly, even when multiple grades of media are present in the one vessel.

Media filtration systems are usually tertiary of part of an overall treatment process. Hydroflux has the skills and expertise to conduct any design and construct project incorporating a wide range of pretreatment equipment or downstream treatment such as membrane filtration or ion exchange. Hydroflux employs qualified civil, mechanical, chemical and electrical engineers plus a team of experienced project managers, site supervisors, commissioning engineers and service technicians based in offices throughout New Zealand providing a local presence throughout the duration of the project.

All projects are conducted under externally approved occupational health and safety, and environmental management systems.

Hydroflux design and construct complete wastewater treatment systems involving many different type of processing equipment including physical / chemical, biological and tertiary treatment to enable reuse.

Hydroflux is Australia’s first Water-tech company to achieve Climate Active certifications which means by engaging with Hydroflux you are supporting positive and verified action on climate change.

Construction of a turnkey wastewater treatment plant at a new food production facility in SA

The Utilities division provides the link to integrating the Hydroflux® businesses by providing a comprehensive support network for customers throughout New Zealand.

Hydroflux Utilities provides virtually any form of water or wastewater management programs including:

Chemical optimisation

Hydroflux has a comprehensive range of chemicals for conditioning water prior to HyPURE RO and for CIP. The most appropriate chemical program will be determined before commissioning based on experience, or test work if possible, and long-term cost-effective chemical supply contracts can be arranged.

Preventative maintenance and service

Our engineers and technicians will discuss service and maintenance programs with you during construction of the treatment plant so that you can be assured that the system will perform consistently from day 1. There are many types of programs available from routine preventative maintenance, periodic service and overhauls, to complete plant operation. Our technicians are available 24/7 to attend to unforeseen breakdowns.